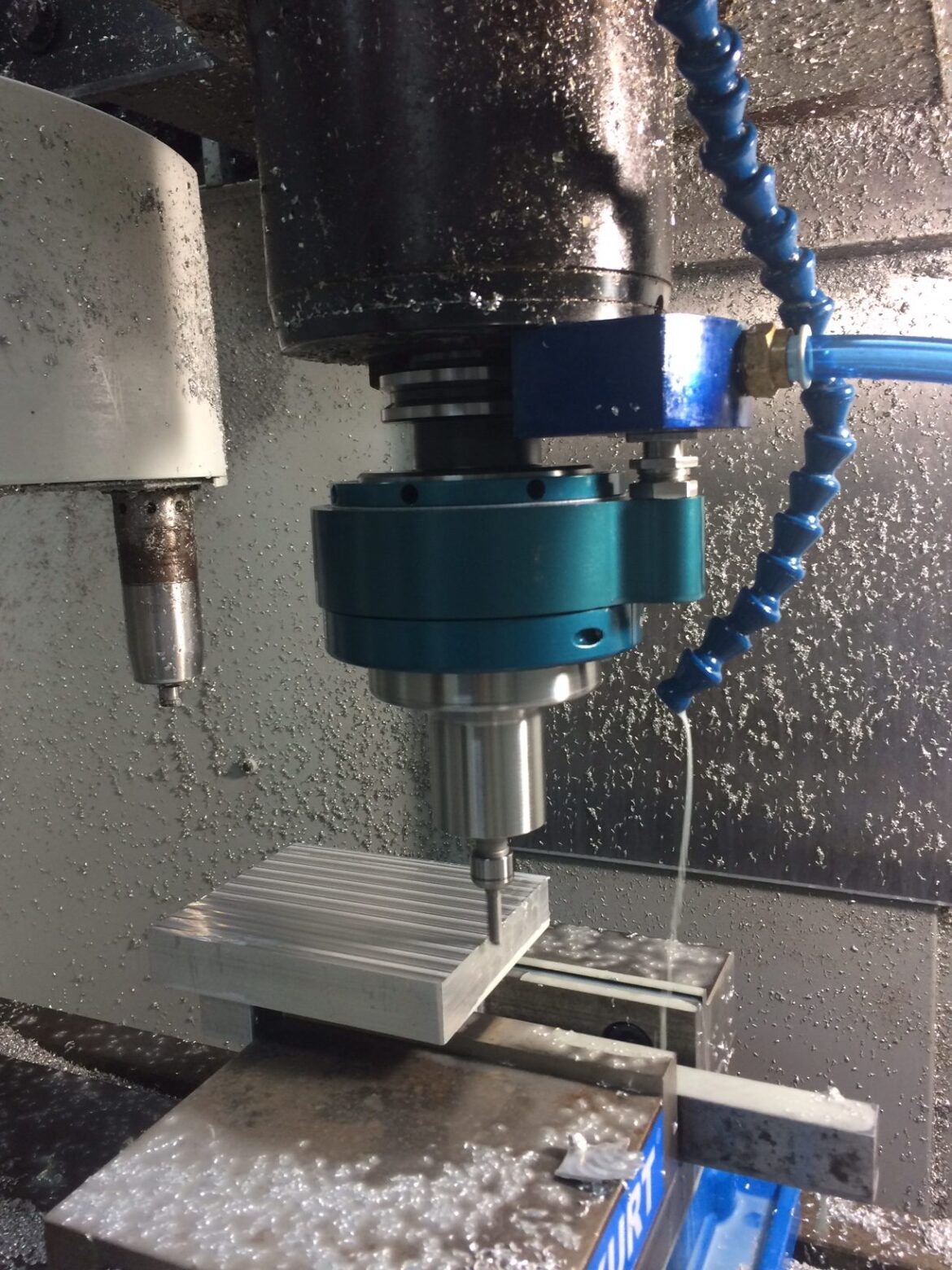

Hurco on Air Turbine Spindles®: The CNC Spindle with 2 Micron Accuracy and No Thermal Growth

Cooled by Turbine Air for 24/7 Operation. No Oil or Control System Required.

Keep continuous tool path engagement on your existing CNC at high speed, even in angles and hard material. Ideal for micro machining with speeds of 25,000 – 90,000 RPM with power to 1.4 HP.

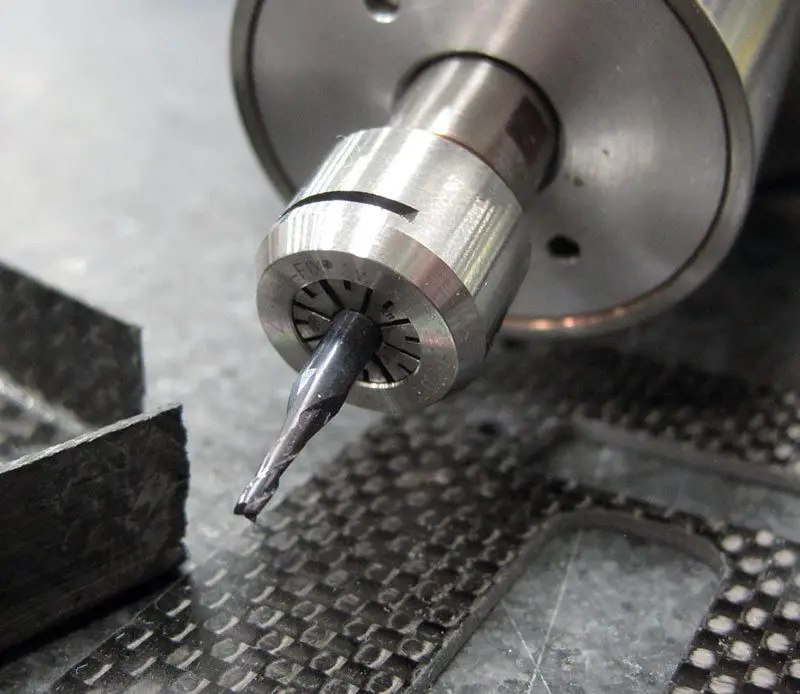

Most of the problems that occur in micromachining come from a lack of RPM and poor dynamic runout. Air Turbine Spindles® use the highest quality runout and balancing systems on the market today. This creates the best dynamic runout accuracy and governed high-speed precision. No need for operator downtime. Automatically load Air Turbine Spindles® with our wrap-around Toolchanger Mounting Assembly into your Hurco VM/VMX.

Auto Tool Change in Your Hurco With This 50,000 RPM CNC Spindle

Manual or Automatic Loading

Saves Time and Money

CAT, BT, DIN, HSK available.

Manual connection also possible.

Videos

Steel Milling at 2,000 mm/min on Hurco VMX by Air Turbine Spindles® 40,000 rpm 650DIN40

C45K Steel Milling on Hurco VMX50i by Air Turbine Spindles® 50,000 rpm, 0.37 kW 625LCAT40

Aluminum contour milled at 500”/min on Hurco VM5i by Air Turbine Spindles® 40,000 rpm 650BT40

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].