Why is this Technology Superior?

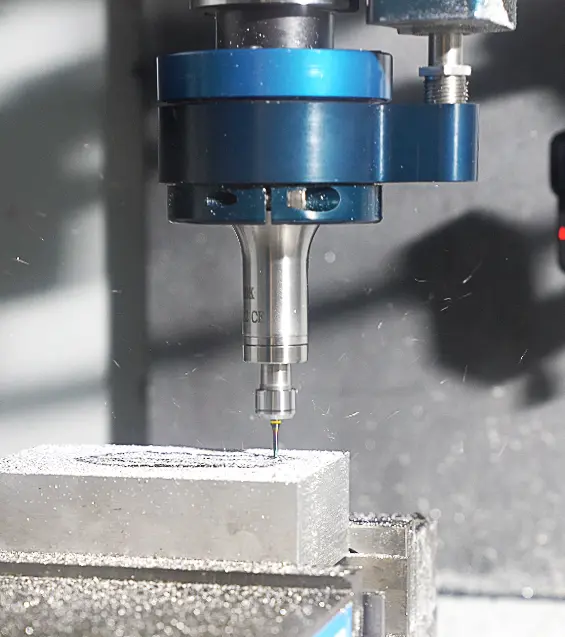

Unlike other products that drop speed as soon as the cutting tool engages Air Turbine Spindles® proprietary governor maintains high cutting speed and torque under load.

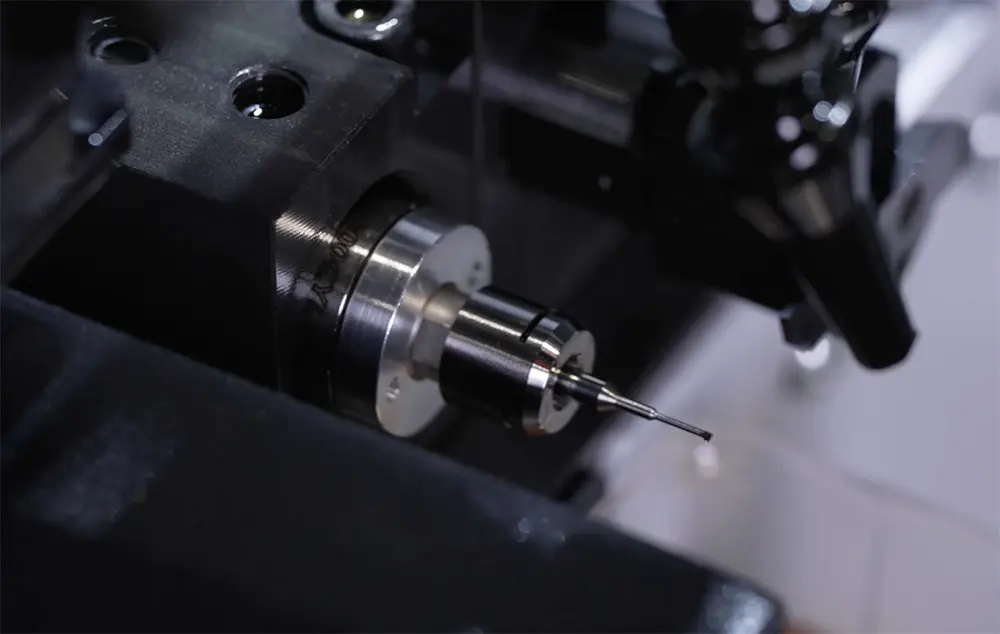

Air Turbine Spindles® use no gears, no high frequency brushes,and no vanes to heat up or burn out. Unlike speeders, multipliers, geared, electric and vane spindles there is no duty cycle and great reliability over 1,000’s of hours if used correctly.

Our internationally patented direct drive technology operates with just two moving parts, generating low friction, no heat and requiring no maintenance or lubrication.

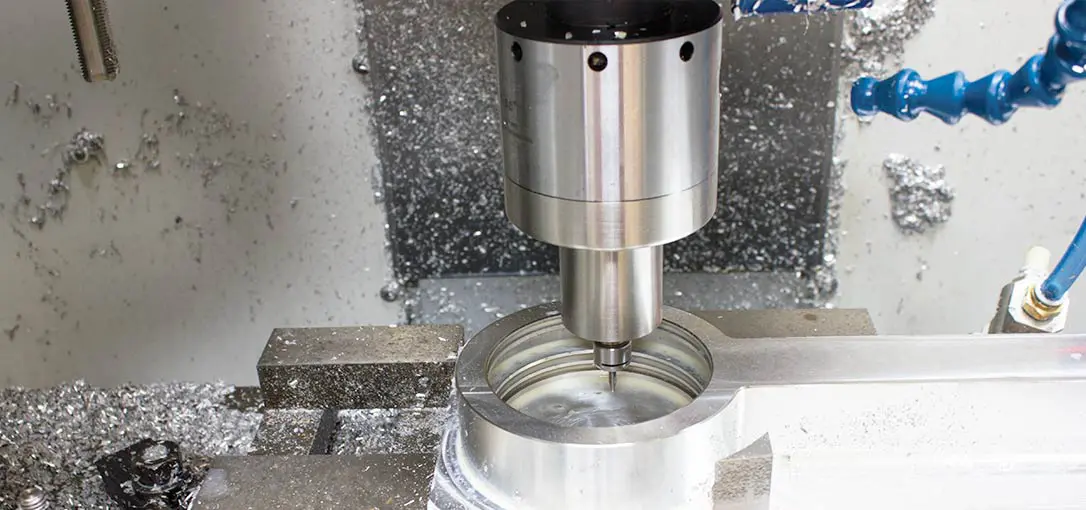

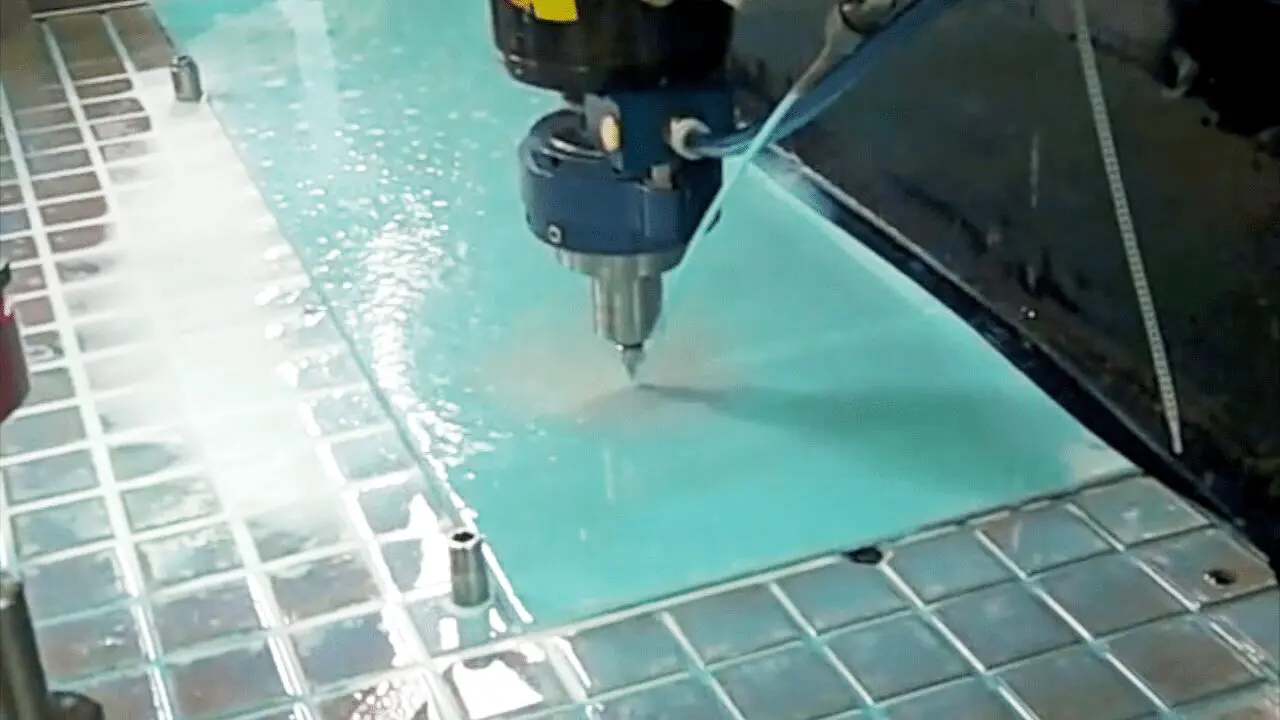

This superior mechanism delivers high cutting speed, reduces cycle time, improves cutting tool performance and life giving you the finest part finish right off your Haas machines.

Enter the next generation of precision milling with 24/7 operation with Air Turbine Tools®.