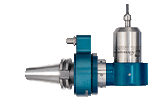

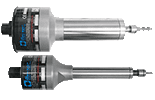

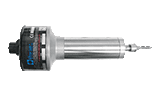

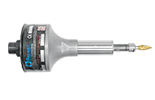

625LJS (50 mm)

625 Extended Barrel CNC Spindle Series

50 mm

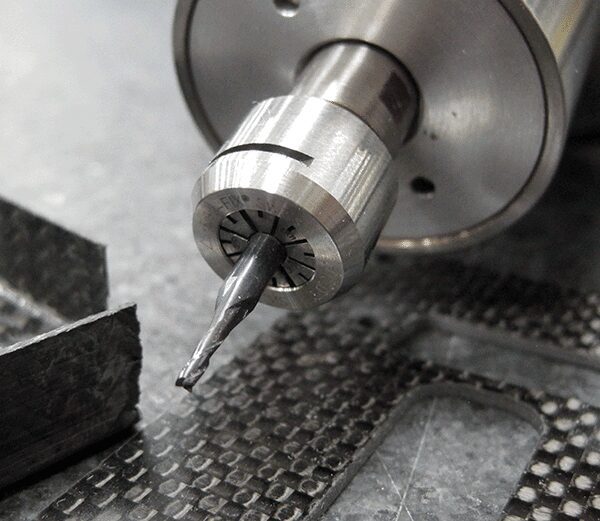

With vibration at just 0.4 mm/sec the 625LJS (50 mm) produces superb accuracy and fast results. The powerful 625LJS (50 mm) is designed for close workpiece operations and machines with very short z-axis travel. Compact and powerful Air Turbine Spindles® 625 unit delivers patented constant governed high speed operation under load up to 0.5 HP / 0.37 kW at 30,000, 40,000 or 50,000 RPM. This results in cuts faster and cleaner – speeding up cycle times and achieving major savings. Fewer moving parts means less vibration and fewer repairs. There are no gears or vanes to lubricate or burn up and the ceramic grease-packed bearings are durable. Specify angular bearings for drilling. Totally oil-free operation eliminates workpiece contamination and oil lubrication using 90 psi (6.2 bar) dry clean oil-free air. The JS version is easy to mount with your selection of tool holder configuration and two selectable air inlet options (through shank or side air feed NPT) (patent pending). No duty cycle.

| 625LJS 50 mm Specifications | |||

| Speed | 30,000 RPM | 40,000 RPM | 50,000 RPM |

| Power Rating | 0.4 HP (0.3 kW) | 0.45 HP (0.34 kW) | 0.5 HP (0.37 kW) |

| Inlet Air Pressure | 90 psi (6.2 bar) | ||

| Air Consumption Idle | 12 CFM (5.66 L/s) | 14 CFM (6.61 L/s) | |

| Air Consumption Working Flow | 11 CFM - 20 CFM (5.19 L/s - 9.44 L/s) |

||

| Air Hoses and Fittings Minimum Size | 6 mm internal diameter | ||

| Sound Level | Less Than 78 dBA | ||

| Max Shank Capacity | ER11 UP - 1/4” (6 mm) | ||

| Spindle Weight | 52 oz (1.47 kg) | ||

| 625LJS (50 mm) Specifications |

| Speed |

| Power Rating |

| Inlet Air Pressure |

| Air Consumption Idle |

| Air Consumption Working Flow |

| Air Hoses and Fittings Minimum Size |

| Sound Level |

| Max Shank Capacity |

| Spindle Weight |

| 30,000 RPM | 40,000 RPM | 50,000 RPM |

| 0.4 HP (0.3 kW) | 0.45 HP (0.34 kW) | 0.5 HP (0.37 kW) |

| 90 psi (6.2 bar) | ||

| 12 CFM (5.66 L/s) | 14 CFM (6.61 L/s) | |

| 11 CFM - 20 CFM (5.19 L/s - 9.44 L/s) |

||

| 6 mm internal diameter | ||

| Less Than 78 dBA | ||

| ER11 UP - 1/4” (6 mm) | ||

| 52 oz (1.47 kg) | ||

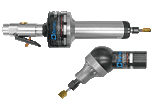

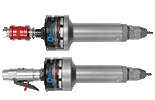

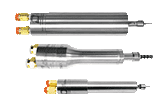

Reach into deep pockets with 1.4 HP with the Air Turbine Extended Barrel CNC Spindle Series

Retrofit Any CNC with High Speed

We retrofit any CNC machine to mill at a constant high speed 24/7 – so any CNC can be a high-speed machine. This includes, but isn’t limited to DMG MORI, Haas, Fanuc Robodrill, Doosan, Hermle, Hurco, GROB, Brother Okuma, Makino and Mazak. Easy installation using selectable air feed inlets – choose side inlet NPT / Stop Block or center through shank/tool holder air feed. HSK, CAT, BT, and DIN Toolholder options are available. Learn more about Air Turbine Spindles on your CNC Machine by visiting their page at the links below.

Add These High Speed Spindles to Your CNC for 5 X Faster Production

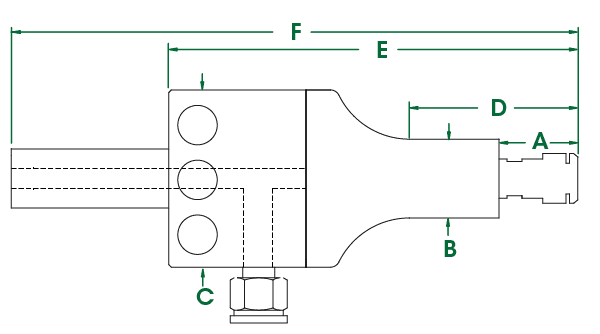

625LJS (50 mm) Dimensions

All fittings, couplings, and hoses must have a minimum of 6 mm internal diameter.

| A | 1.00” (25mm) |

| B | 1.00” (25mm) |

| C | 2.25” (57mm) |

| D | 2.16” (55mm) |

| E | 5.22” (133mm) |

| F | 7.22” (183mm) |

Equipment

Included Equipment

Standard Equipment

ER11 UP collet system. 1/4” or 6 mm standard, other sizes are available. Oil-free 90 psi / 6.2 bar clean, dry air supply required.

| Accessories Models | Part Numbers |

|---|---|

| High Flow Filter / Regulator / Extractor | 30008 |

| Tube 10 mm O.D. - 6.5 mm I.D. (order by foot) | 16508 |

| Hose & Fitting - 10 mm O.D. - 6.5mm I.D. - 12’ | 30043 |

| ER11- 1/4" | ER11 - 6 mm | ||

|---|---|---|---|

| Speed RPM | Part Numbers | Speed RPM | Part Numbers |

| 30,000 | 65096 | 30,000 | 65097 |

| 40,000 | 65098 | 40,000 | 65099 |

| 50,000 | 65100 | 50,000 | 65101 |

Videos

Aluminum Engraving at 5,000 mm/min - The CNC Spindle that DRASTICALLY Reduces Cycle Times

Aluminum Milling on DMG DMU 80 T by Air Turbine Spindles® 50,000 rpm, 0.37 kW 625L 50mm

Aluminum Milling on Hurco VCX600i by Air Turbine Spindles® 50,000 rpm, 0.37 kW 625L

Service & Support

Support is always available from our technical team in the USA, Germany and Mexico. Repair Service is available in Florida and Munich.

Call our factory technicians at +1-561-994-0500 or email us at [email protected].