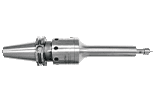

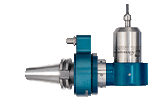

602HSK-A63

602 CNC Spindle Series

Integration of the popular HSK-A63 tool holder into 602 spindle housing cuts vibration and improves accuracy and rigidity. Rigid steel construction in one piece with the tool holder also cuts the height of the unit. Air Turbine Spindles® patented constant governed high-speed operation under load cuts faster and cleaner – speeding up cycle times and achieving major savings. Your solution for fast cutting with small end mills and drills, finishing or marking. High-speed cutting improves finish quality and accuracy with a fast light pass of your tool. At 40,000, 50,000, 65,000 or 90,000 RPM tool coatings achieve the required temperatures to extend endmill life-saving money as well as accelerating production. 0.2 HP (0.15 kW). No duty cycle.

| 602HSK-A63 Specifications | ||||

| Speed | 40,000 RPM | 50,000 RPM | 65,000 RPM | 90,000 RPM |

| Power Rating | 0.15 HP (0.11 kW) | 0.2 HP (0.15 kW) | ||

| Inlet Air Pressure | 90 psi (6.2 bar) | |||

| Air Consumption Idle | 4.5 CFM (2.1 L/s) | 5 CFM (2.36 L/s) | ||

| Air Consumption Working Flow | 5 CFM - 6 CFM (2.36 L/s - 2.83 L/s) |

|||

| Air Hoses and Fittings Minimum Size | 4 mm internal diameter | |||

| Sound Level | Less Than 78 dBA | |||

| Max Shank Capacity | ER8 UP - 1/8" (3 mm) | |||

| Spindle Weight | 46.4 oz (1.32 kg) | |||

| 602HSK-A63 Specifications |

| Speed |

| Power Rating |

| Inlet Air Pressure |

| Air Consumption Idle |

| Air Consumption Working Flow |

| Air Hoses and Fittings Minimum Size |

| Sound Level |

| Max Shank Capacity |

| Spindle Weight |

| 40,000 RPM | 50,000 RPM | 65,000 RPM | 90,000 RPM |

| 0.15 HP (0.11 kW) | 0.2 HP (0.15 kW) | ||

| 90 psi (6.2 bar) | |||

| 4.5 CFM (2.1 L/s) | 5 CFM (2.36 L/s) | ||

| 5 CFM - 6 CFM (2.36 L/s - 2.83 L/s) |

|||

| 4 mm internal diameter | |||

| Less Than 78 dBA | |||

| ER8 UP - 1/8" (3 mm) | |||

| 46.4 oz (1.32 kg) | |||

90,000 RPM 602 version is recommended for only special applications with micro end mills. Please call +1.561.994.0500 for more information.

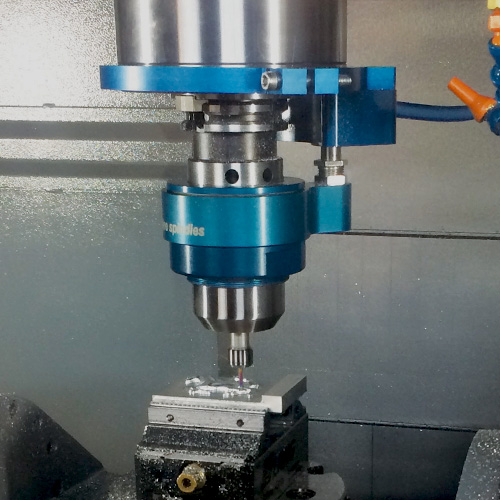

Retrofit Any CNC with High Speed

We retrofit any CNC machine to mill at a constant high speed 24/7 – so any CNC can be a high-speed machine. This includes, but isn’t limited to DMG MORI, Haas, Fanuc Robodrill, Doosan, Hermle, Hurco, GROB, Brother Okuma, Makino and Mazak. Easy installation using selectable air feed inlets – choose side inlet NPT / Stop Block or center through shank/tool holder air feed. HSK, CAT, BT, and DIN Toolholder options are available. Learn more about Air Turbine Spindles on your CNC Machine by visiting their page at the links below.

Add These High Speed Spindles to Your CNC for 5 X Faster Production

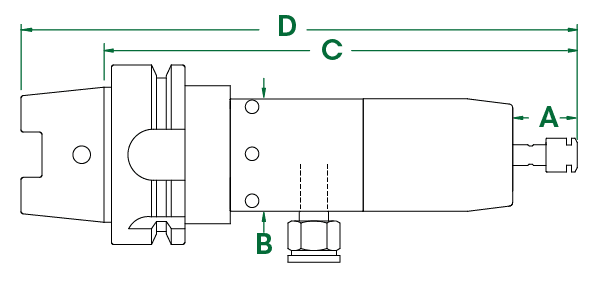

602HSK-A63 Dimensions

All fittings, couplings, and hoses must have a minimum of 4 mm internal diameter.

| 602HSK-A63 Dimensions | |||

| A | 0.75" (19 mm) | C | 5.55” (141 mm) |

| B | Ø 1.57” (40 mm) | D | 6.69” (170 mm) |

| 602HSK-A63 Dimensions | |

| A | 0.75" (19 mm) |

| B | Ø 1.57” (40 mm) |

| C | 5.55” (141 mm) |

| D | 6.69” (170 mm) |

Equipment

Included Equipment

Standard Equipment

ER8 UP collet system. 1/8” or 3 mm standard, other sizes are available. Oil-free 90 psi / 6.2 bar clean, dry air supply required.

| Accessories Models | Part Numbers |

|---|---|

| High Flow Filter / Regulator / Extractor | 30008 |

| Tube 10 mm O.D. - 6.5 mm I.D. (order by foot) | 16508 |

| Hose & Fitting - 10 mm O.D. - 6.5mm I.D. - 12’ | 30043 |

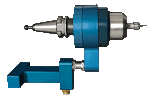

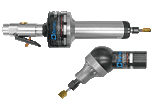

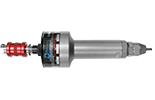

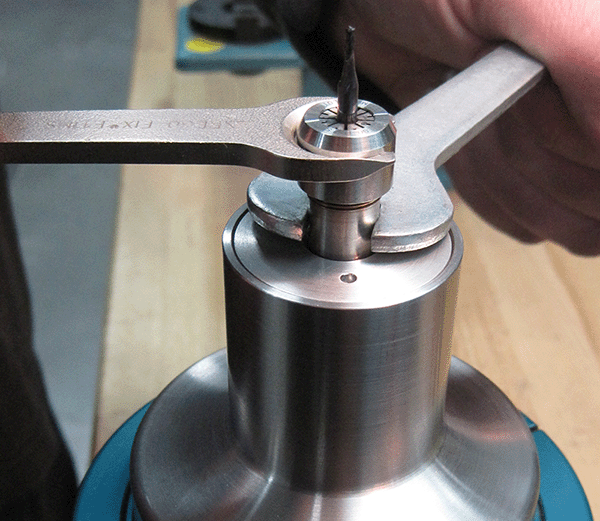

Automatically Tool Change on your CNC

Automatically load Air Turbine Spindles® in CNC machines with our patented wrap-around Toolchanger Mounting Assembly (TMA). This option allows CNC tool-changers to automatically load/unload our family of high-speed precision spindles using a proprietary collar system and mounting block or ring around the CNC spindle integrated to the right side of the CNC spindle in minutes.

For machines that have an air blast line or coolant channel that can be used to supply sufficient CFM / L/s airflow volume; Air Turbine Spindles® can tool change without the Toolchanger Mounting Assembly. All HSK spindles can be used with center air feed if air supply line has sufficient ID.

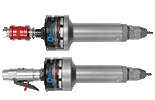

Screw In Mounting Block

Two Piece Ring and Block

Drill Tap

Mounting blocks or rings compatible with Haas, Hurco, Doosan, Robodrill, Hardinge, DMG, Brother, Okuma, and all other CNC’s are available. We are accustomed to developing custom solutions for any CNC. A universal block can be provided for drilling your CNC screw positions. Installation kits are available. The TMA block remains on the CNC spindle for normal tool changes, even if not using the Air Turbine Spindles® as it will not interfere when using the main spindle.

TMA Assembly Includes

- Mounting block or ring assembly

- Spindle manifold collar with adjustable height connector to block

Auto Tool Change your Air Turbine Spindle® with Through Spindle Air

Auto Tool Change your Air Turbine Spindle® with the Tool Changer Mounting Assembly

| ER8 - 1/8" | ER8 - 3mm | ||

|---|---|---|---|

| Speed RPM | Part Numbers | Speed RPM | Part Numbers |

| 40,000 | 64274 | 40,000 | 64275 |

| 50,000 | 64276 | 50,000 | 64277 |

| 65,000 | 64278 | 65,000 | 64279 |

| 90,000 | 64280 | 90,000 | 64281 |

Videos

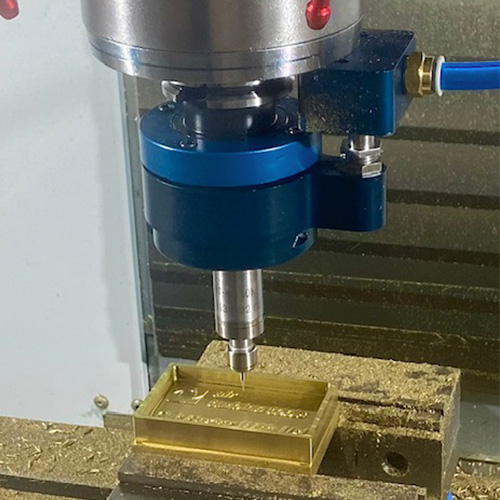

Brass Milling at 504”/min on Haas TM-2 by Air Turbine Spindles® 65,000 rpm 602JS

Painted Aluminum milled at 180"/min on Fadal CNC by Air Turbine Spindles® 65,000 rpm 602JS

Aluminum Engraving at 25”/min on Haas Mini Mill by Air Turbine Spindles® 65,000 rpm 602CAT40

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].