What is High-Speed Machining?

High-speed machining (HSM) is transforming modern manufacturing, enabling businesses to produce high-precision parts with unprecedented speed. With spindle speeds reaching up to 90,000 RPM, HSM is a crucial advancement for industries requiring both efficiency and accuracy, such as aerospace, electronics, medical device manufacturing and mold-making.

HSM operates at spindle speeds of 40,000 to 90,000 RPM—far beyond conventional machining’s 20,000 RPM limit. This approach reduces cycle times, enhances precision and lowers operational costs, making it indispensable for efficient CNC machining.

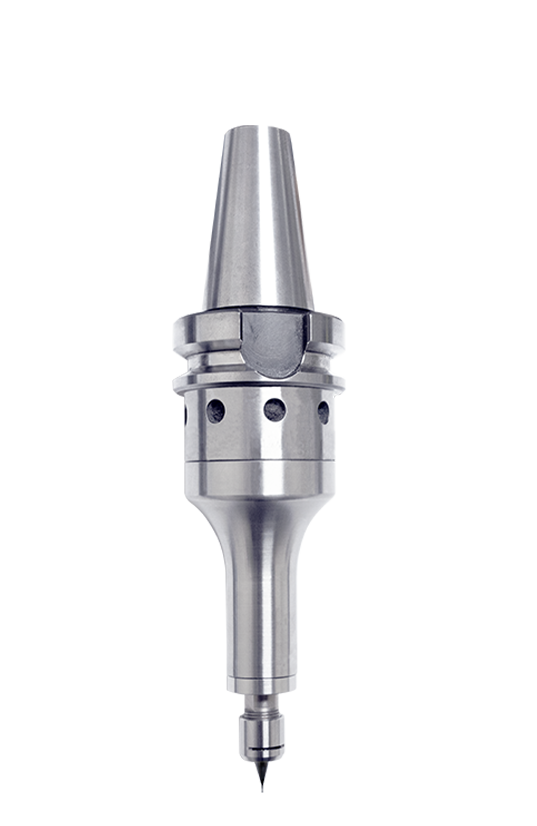

Add These High Speed Spindles to Your CNC for 5 X Faster Production

What are the Key Benefits of High-Speed Machining?

One of the key advantages of HSM is the dramatic reduction in cycle times. CNC machining at speeds of 50,000 RPM using a spindle that maintains high speed on the toolpath allows for up to ten times faster production, significantly increasing machining efficiency.

Another major benefit is the enhanced surface quality. High surface feet per minute (SFM) and lighter, layered cuts reduce vibration and heat buildup, producing smoother, more consistent finishes—essential for aerospace-grade aluminum, titanium and medical components.

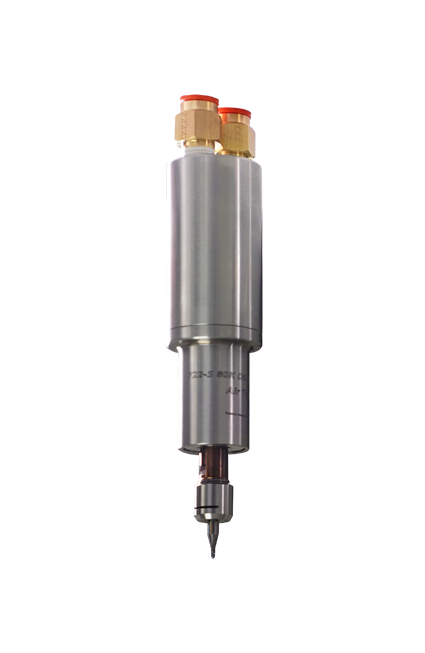

Make Stainless Steel Fly At 80,000 RPM on Your Lathe

Additionally,

HSM extends tool life by ensuring consistent spindle speeds that prevent tool breakage. Efficient heat dissipation resulting from HSM programming techniques further extends tool longevity, reducing replacement costs for micro-machining industries.

This machining technique also offers versatility across materials, delivering precision across a wide range of substrates, including steel, aluminum, titanium, composites, plastics and ceramics. This makes HSM ideal for applications such as mold-making, gear tooth grooving and deburring and medical implant manufacturing.

Debunking Common Myths About High-Speed Machining

There are several common misconceptions about HSM. One of the most prevalent myths is that air tools lack power. In reality, today’s governed air-powered spindles deliver both speed and torque, making them effective in CNC milling, routing and finishing applications.

Another misconception is that high-speed spindles have a duty cycle and are unreliable. However, modern air-powered spindles generate no heat with no maintenance and no thermal effects on accuracy, making them perfect for 24/7 CNC machining operations.

There is also a belief that HSM is only for small tools, but while excellent for micro tools, it is also highly effective for mold machining, contouring, engraving, CNC deburring and machining complex geometries cleanly in materials like graphite, acrylic and fiberglass with no fiber break-out.

Best Practices for Implementing High-Speed Machining

Implementing HSM effectively requires following best practices. Optimizing CNC programming by using high feed rates and shallow cuts improves efficiency, while pecking cycles help control heat build-up during drilling.

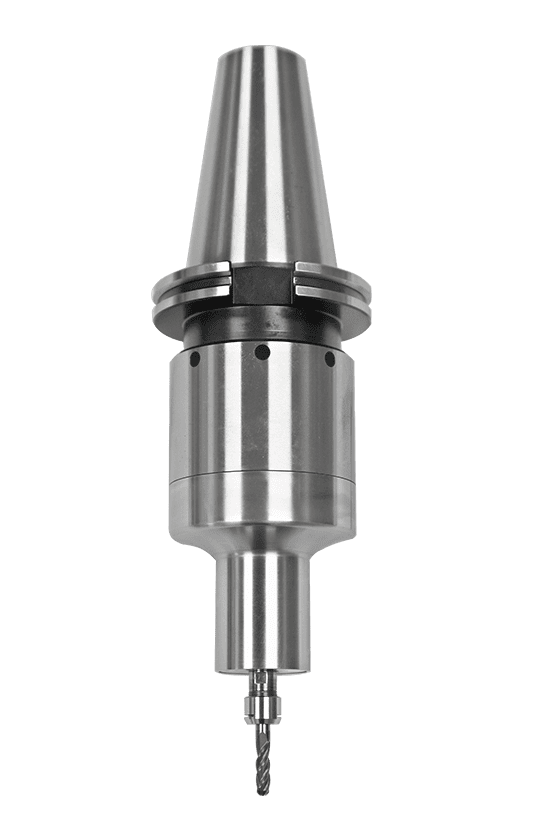

Faster Production with a Finer Finish using High Speed Air Turbine Live Tools®

Using balanced cutting tools, such as multi-flute carbide tools, distributes load evenly and enhances chip evacuation. Selecting the right spindle technology is also essential – Air Turbine Spindles® set a new standard by maintaining consistent RPM’s at 25,000 to 90,000 RPM in cut with power to 1.4 HP without any heat, ensuring stable, high-speed performance.

A simple set-up and maintenance is another critical factor, as air-powered spindles require no wiring, control boxes, or lubrication, offering easy integration and continuous operation with full ATC on any CNC.

Learn More About Air Turbine Spindles® and Air Turbine Live Tools®

Service & Support

Support is always available from our technical team in the USA, Germany and Mexico. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].