INDEX

►

►

►

►

►

►

►

High-Speed Machining Innovations

In Hanover, Germany, the world of manufacturing engineering gathered in September 2023 at EMO to unveil their latest products. Air Turbine Tools® exhibited 150 powerful high speed CNC spindles, hand tools, motors and live tools.

The Air Turbine Tools® booth showcased a diverse range of high-speed precision tools with live cutting demonstrations at 25,000 RPM to 90,000 RPM on leading machines such as Tornos, Fanuc and Hurco. Air Turbine Tools® also introduced new additions, such as:

30+ Years of Proven Patented Innovation

With three decades of meticulous engineering and development, Air Turbine Tools® patented high speed tools stand unmatched. They deliver high-speed under load machining with cutting tools under 6mm or 1/4”, providing up to 1.4HP and exceptional accuracy at 2-micron TIR (Total Indicator Runout).

What sets our patented products apart is the combination of high speed AND power, distinguishing them from spindle speeders, multipliers and non-governed electric spindles, and motors that drop speed in cut.

Join us in exploring Air Turbine Tools® unmatched technology and reviewing revolutionary products launched at EMO Hannover. Discover how our innovations contribute to enhancing manufacturing productivity for you!

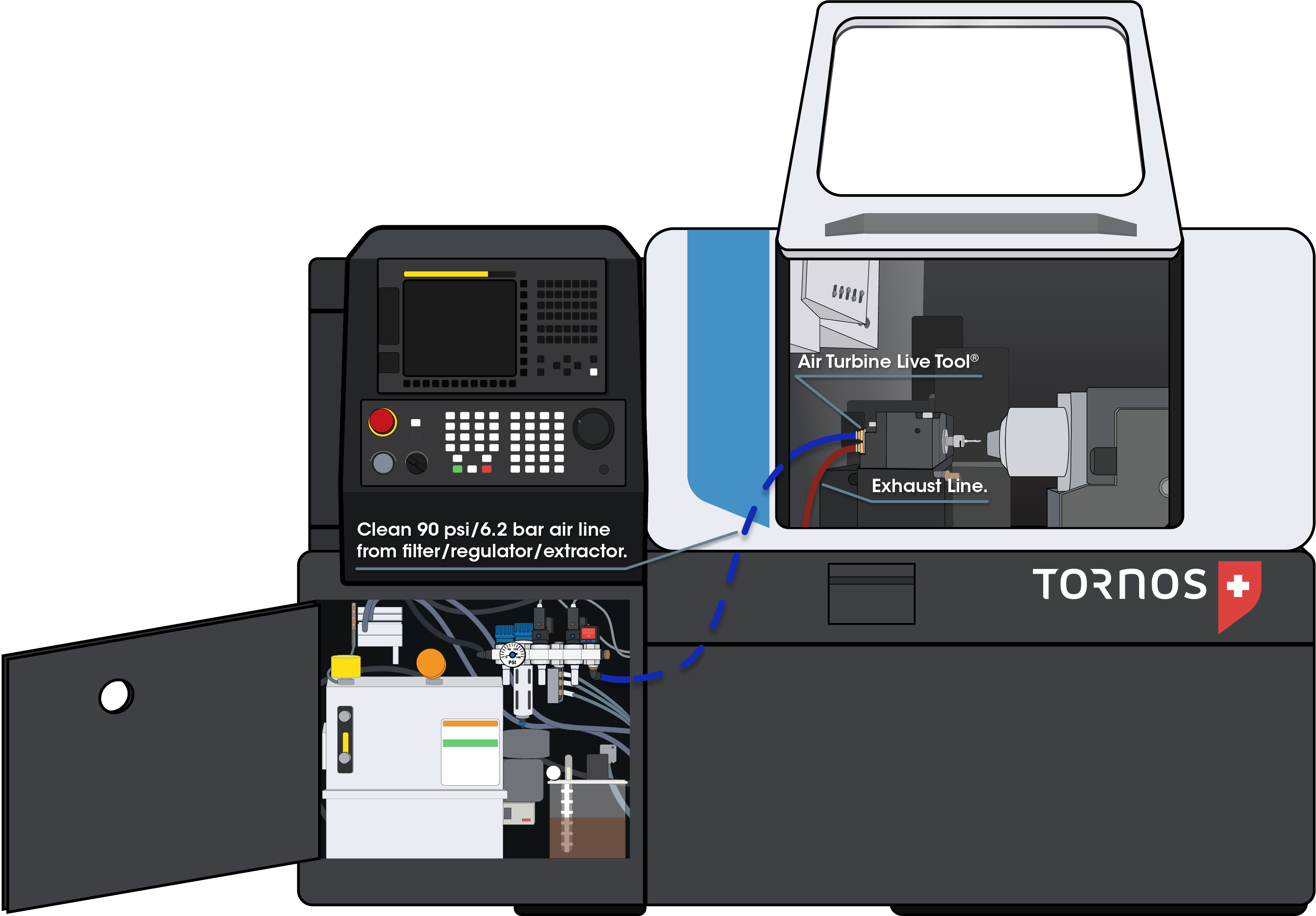

Get 80,000 RPM on a Tornos Swiss Machine

The spotlight was on governed 60,000 RPM and 80,000 RPM Air Turbine Live Tool® 825CX mounted on a Tornos Swiss machine. We were honoured to welcome Tornos CEO, Jen Thing, to our booth, where he identified the advantages of integrating Air Turbine Live Tools® on Tornos lathes. During this exchange, he shared invaluable insights into the collaboration between Air Turbine Tools® and Tornos, emphasizing,

“Together, we are shaping the future of high-speed lathe manufacturing, driving efficiency and excellence in the industry.”

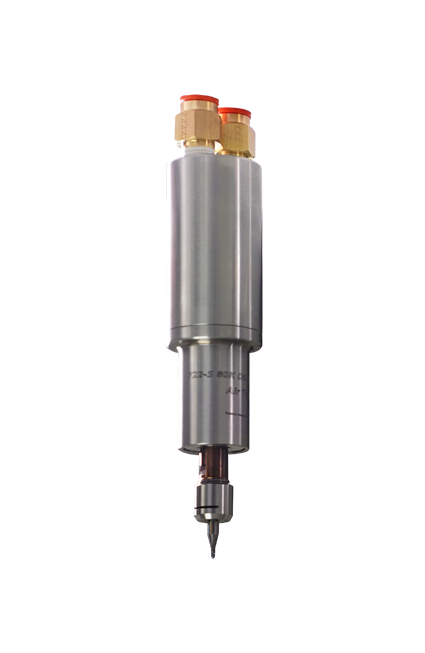

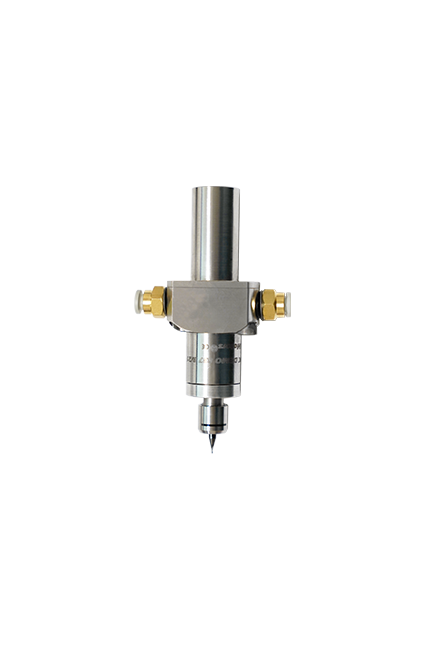

How do Air Turbine Live Tools® work?

These cutting-edge live tools integrate into your lathe boring bar holder, requiring only an airline with 90 psi / 6.2 bar air. With this straightforward setup, your lathe operates at 60,000 RPM and 80,000 RPM, maintaining consistent high speed in cut with no heat and no duty cycle. This seamless solution not only slashes cycle times 6-10x and improves cutting tool performance but also elevates the finish quality of your workpieces. High-speed precision machining on your lathe significantly boost productivity.

Keep up with Production Pressure with 80,000 RPM Air Turbine Live Tools®

Productivity Case Study

Imagine you have a lathe running a small tool at 6,000 RPM. Now, integrating an Air Turbine Live Tools® at 80,000 RPM. You are cutting more than 13x faster and can manufacture 13x more parts in the same amount of time. When working with small cutting tools on lathes, high RPMs are vital to optimize micro cutting tool performance and life.

How do you calculate the cutting tool feed rate at high speed?

The solution is simple yet remarkably effective. By multiplying the existing feed rate by 6.5, you achieve the optimal surface footage for the tools. It’s a small calculation that yields significant results, transforming the efficiency and precision of the machining process.

Air Turbine Live Tools® turn your lathe into a high speed lathe, ensuring not just speed, but precision, cutting tool optimization and increased productivity of machining and turning operations.

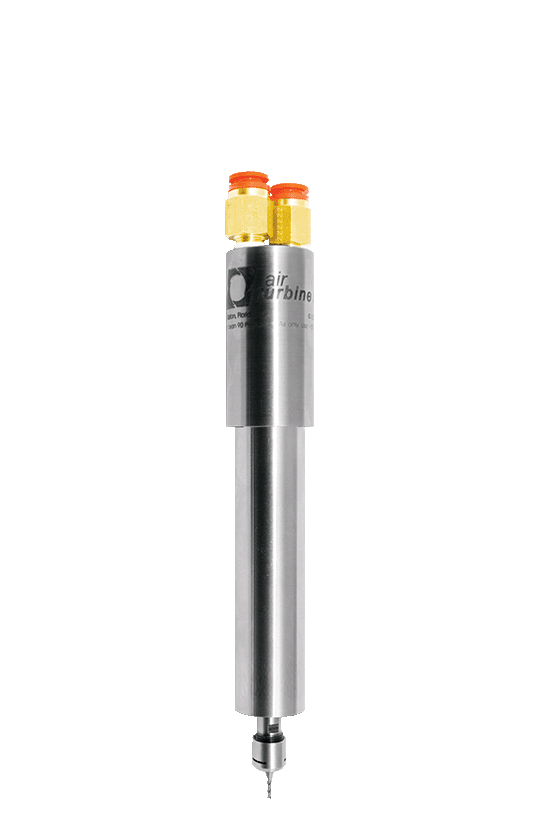

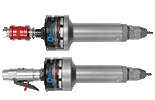

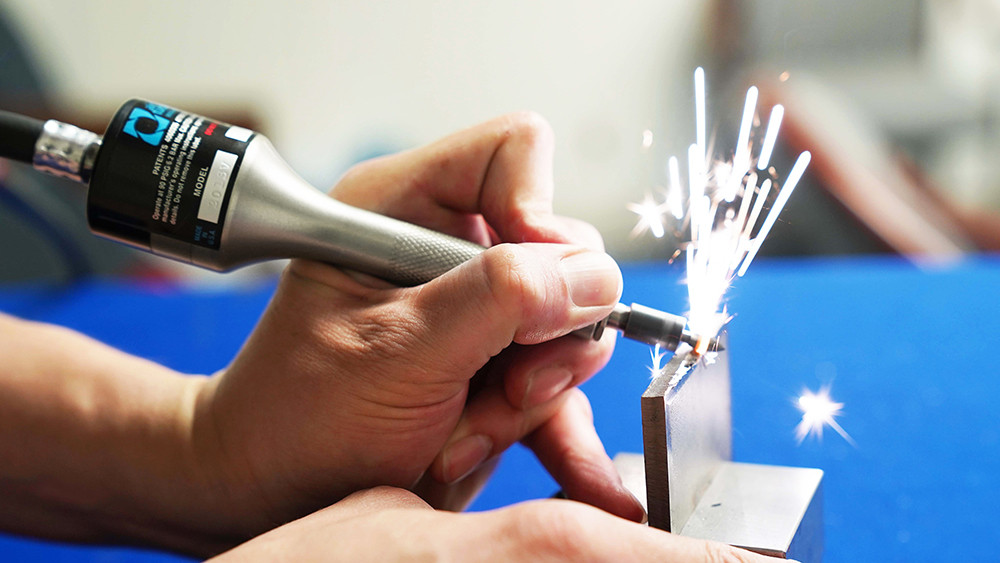

Hands On Air Turbine Hand Tools® Visitors Testing

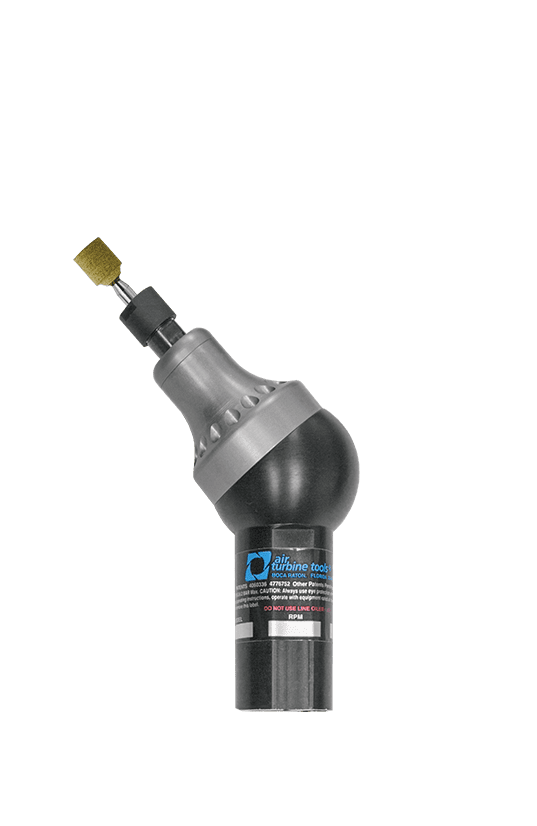

Visitors at EMO had the opportunity to personally test the revolutionary power and comfort of Air Turbine Tools® with hands-on live deburring and cutting in our grinding pyramid. Witness sparks fly as visitors operate the tools at speeds ranging from 25,000 to 90,000 RPM, harnessing up to 1.4 HP. Our tools require just a light hand to guide your cutting tool and operate with the lowest vibration and weight of any range.

These Air Tools Cut Steel and Stress

No More Sacrificing Comfort and Safety for Performance!

Air Turbine Tools® stand out not only for their unmatched performance in cut but also for their whisper-quiet operation (under 67 dba), ultra-low vibration. You’ll enjoy feather-light weight. This tool remains cool even after prolonged use. These advantages mean operators face no working time limits or health issues such as white finger and less risk of carpal tunnel. Add to that the convenience of no maintenance requirements and the elimination of messy oil, making these light powerful tools a cleaner choice for your workspace.

It gives us immense pride when users approach us at trade shows, expressing that Air Turbine Tools® rank as the best grinders and routers they’ve ever used, with years of reliable use.

We frequently hear from customers with their 20-year-old Air Turbine Tools® still going strong! Our USA-manufactured hand tools defy the disposable norm; they are engineered with durability in mind, built to withstand years of use when operated correctly. Air Turbine Tools® handheld pneumatic grinders, routers, rotary deburring tools, and pencil grinders not only reduce repair cost but also safeguard the safety of operators worldwide.

Transform your work experience with Air Turbine Tools®

Whether you’re engraving intricate details, repairing turbine blades or die grinding, Air Turbine Tools® provide the unmatched power and reliability needed to excel in your work. Our hand tools revolutionize your processes and work experience from deburring to engraving and beyond!

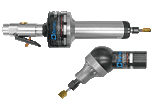

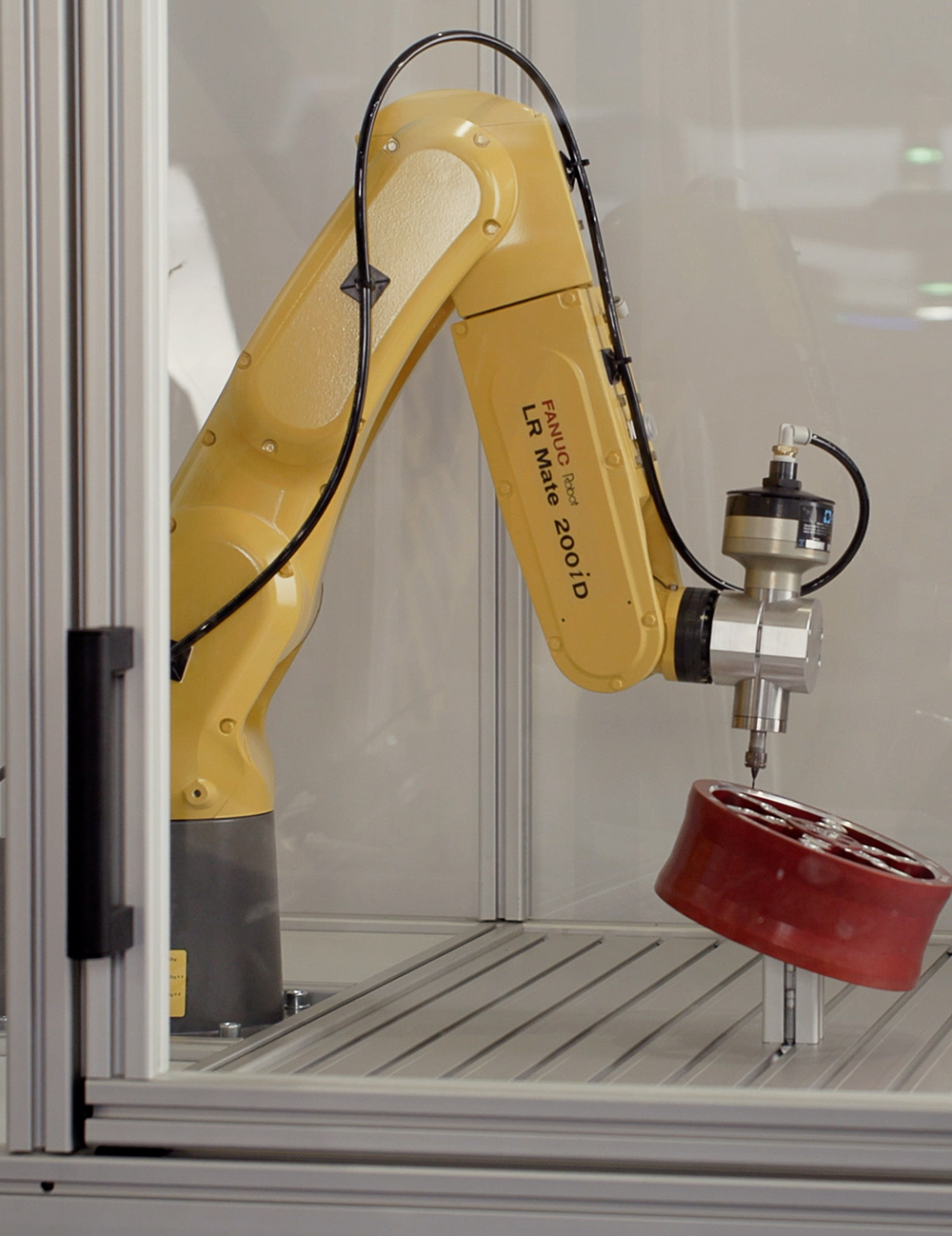

Robust Deburring on Fanuc Robot Arm

Air Turbine Motors® redefine high-speed robotic deburring, grinding, milling, finishing and drilling. Our motors operate at speeds from 25,000 RPM to 65,000 RPM with collet sizes up to ER11. These light powerful motors deliver impeccable surface finishes in a fraction of the time with no duty cycle.

Easily mounted on the steel shaft these light motors do not vibrate on the robot arm which enhances accuracy and tool life.

Increase Your Revenue With an Air Powered Motor

Reduce your Cycle Times with Direct Drive Reliability

Air Turbine Motors® featured a demonstration of robotic wheel deburring EOA (end of arm) effector on a Fanuc robot arm. Simplicity is key—just connect 90 psi (6.2 bar) air. There’s no need for wiring or a control box.

These motors operate at a constant high speed, cutting 24/7. There are also no gears brushes or vanes to heat up or thermally expand. Air Turbine Motors® are direct drives with only 2 moving parts.

This results in low friction, no heat and great reliability. These turbines operate without lubrication and do not need oil and maintenance.

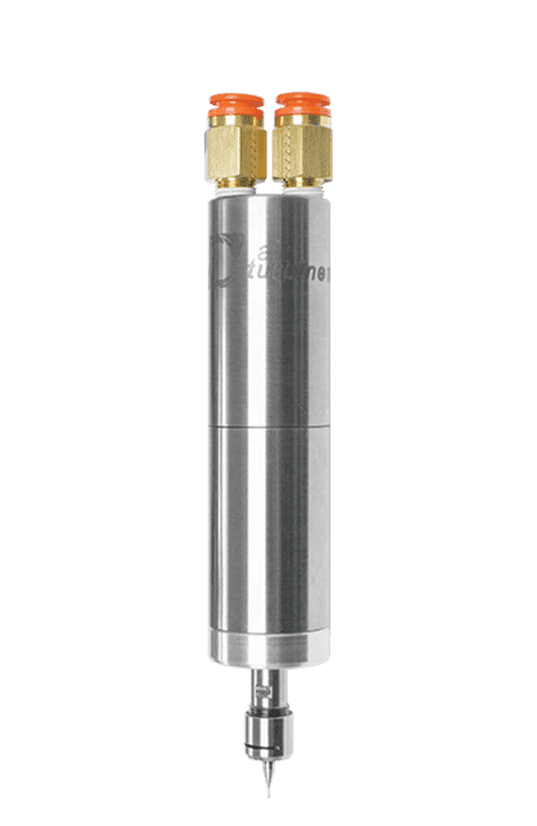

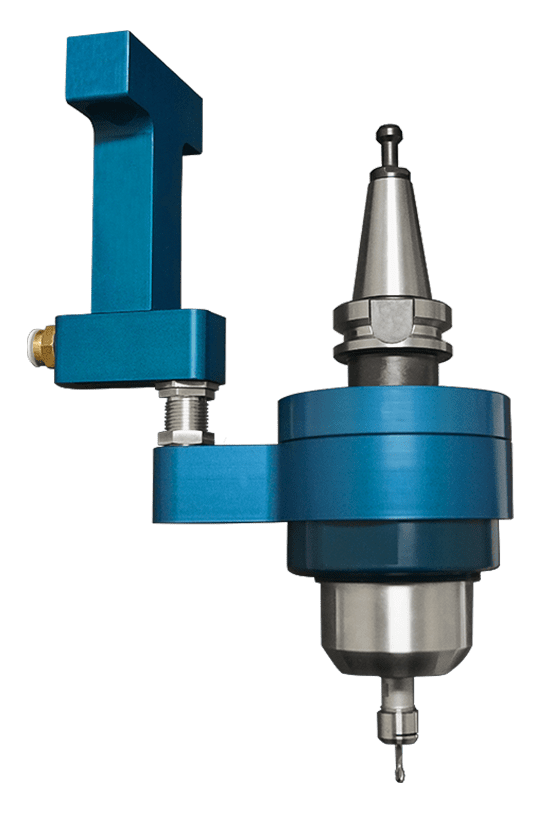

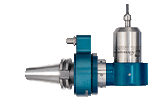

50,000 RPM Air Turbine Spindles®

on a Hurco CNC machine

Air Turbine Spindles® were in operation on our stand cutting live at 50,000 RPM on a Hurco CNC Machine. Hurco’s Senior Applications Engineer, Herr Florian Kerkau, commented that Air Turbine Spindles® elevate the versatility of the Hurco machine adding high speed to the machine capability.

"Air Turbine Spindles® are a great way to increase the versatility of the machine and turning it into a high-efficency machining center with 50,000 RPM."

Add These High Speed Spindles to Your CNC for 5 X Faster Production

Drastically Enhance the

Performance of your CNC Machine

Air Turbine Spindles® enable high-speed, precision machining on any CNC machine. milling at speeds of 25,000 to 90,000 RPM with power up to 1.4 HP, Air Turbine Spindles® dramatically accelerates cutting with tools under ¼” / 8 mm optimizing tool performance on any CNC.

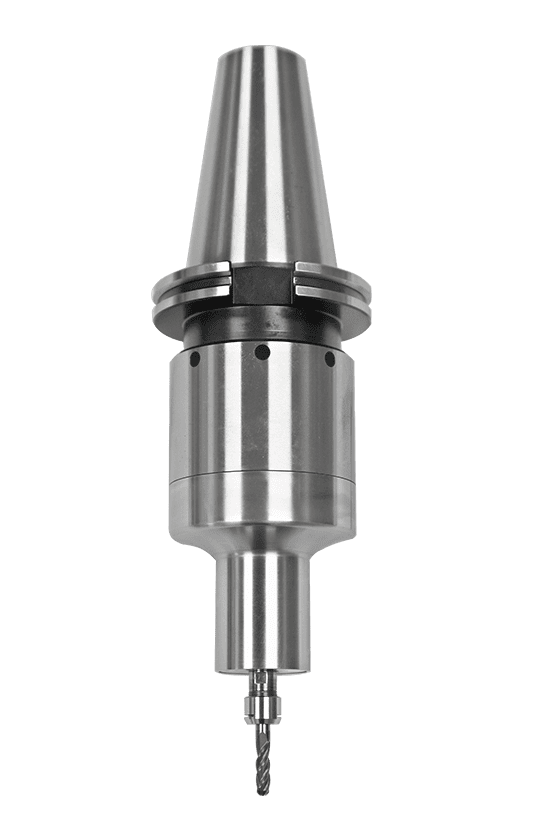

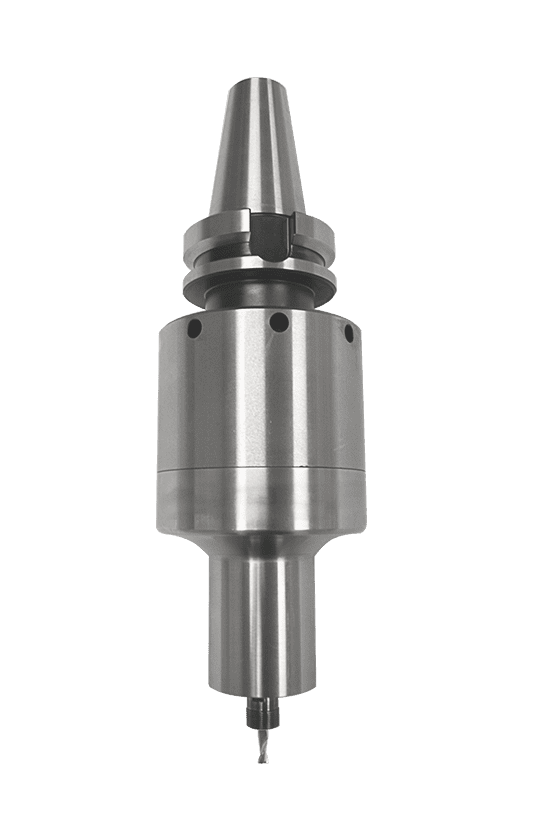

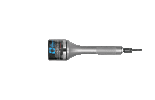

Introducing The New Low Profile

80,000 RPM Mini Air Turbine Spindle®

Unveiled on a Fanuc Robodrill with great anticipation at EMO 2023, the new low profile 80,000 RPM 600X Series Air Turbine Spindle® marks a significant advance in machining technology. The low profile of the 600 series spindle opens new possibilities for machinists, allowing the retrofitting of our governed high-speed spindles into machines with limited clearance.

“We have a long partnership with Air Turbine Tools® and we exhibit our Robodrill on their booth together we achieve good results in the mold making.”

These Micro High Speed Spindles Cut Cycle Times and Reduce Wear and Tear on the Main Spindle

Optimize Your Tool Performance

The applications of the 600X Series Air Turbine Spindle® with air through the spindle and full auto tool change capability are diverse, ranging from the precise milling of medical devices to micro-machining delicate electronic components that demand micro cuts. The remarkable high RPM of this 80,000 RPM spindle translates into substantial cycle time reductions, enabling the production of more parts on your machine.

This New CNC Spindle Mills Molds at 80,000 RPM on Robodrill

Increase Your Production Rate Today

EMO Hannover Trade Show in 2023 was the ideal backdrop for Air Turbine Tools® to unveil cutting-edge high-speed machining innovations.

Contact Us Today To Get a Consultation on

How We Can Integrate Into Your Application

Success in high-speed machining awaits. Air Turbine Tools® is your trusted guide on your journey to reduce your costs and improve productivity.

Service & Support

Support is always available from our technical team in the USA, Germany and Mexico. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].