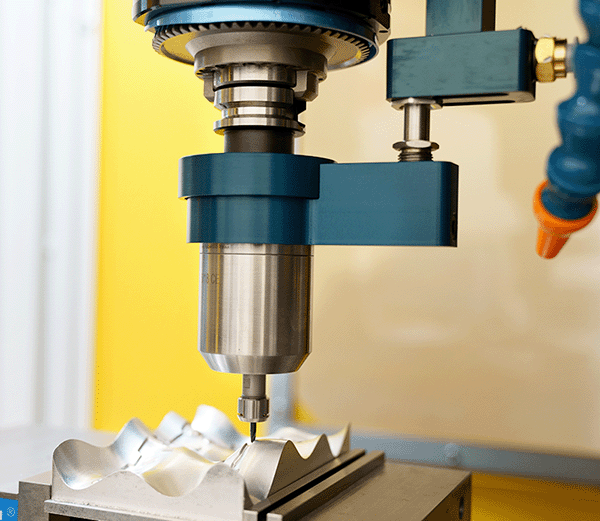

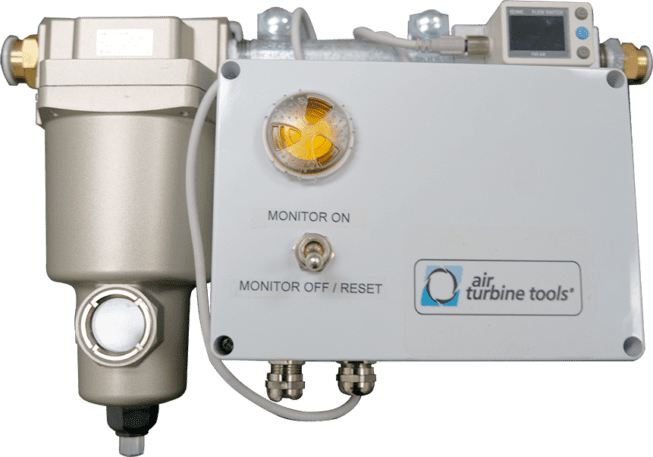

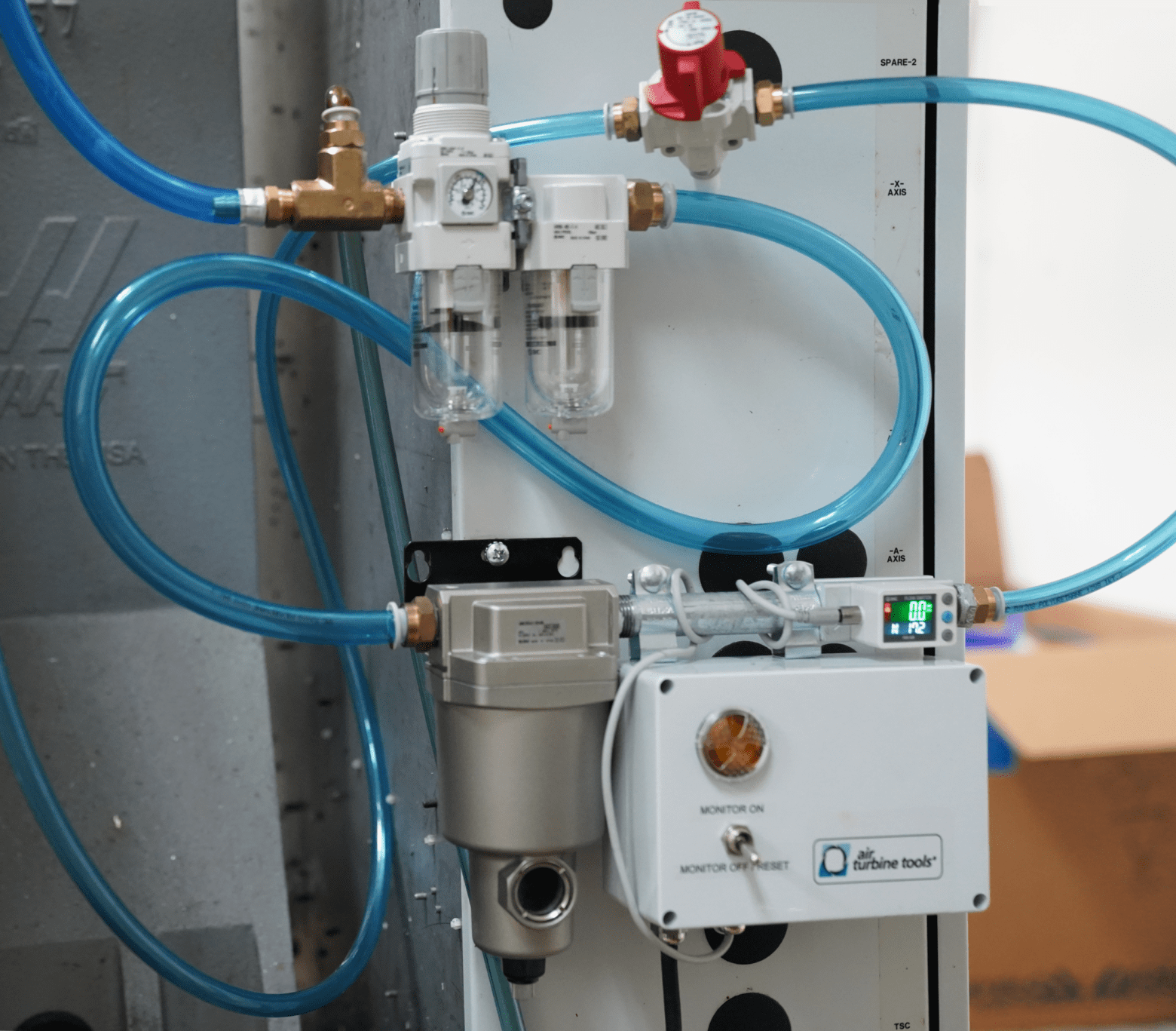

Tool Breakage Alarm System

CNC Spindle Accessories

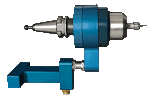

Air Turbine Tools® TOOL BREAKAGE ALARM™ stops Lost Machine Time, Scrapped Parts and Machine Damage.

How does it work?

As your cutting tool follows the programmed tool path at high speed our tool breakage detector system monitors CFM/L/s air flow for deviation from a sensitive baseline record of compressed air consumption. Drops in air pressure or CFM flow will destroy your part and tool.

Choice of Klaxon/ Light Alarm or Program Control

If your cutting tool breaks our TOOL BREAKAGE ALARM™ activates to alert the operator with a light and/or a klaxon. You can also program it to stop your machine automatically if you connect your CNC or robot control to the TOOL BREAKAGE ALARM SYSTEM‘s™ external port – permitting unattended operation 24/7 and big savings. Intervention limits damage to your parts and spindles and reduces loss of production yield.

Now you can detect air flow cavitation to your spindle or motor whether from the diversion to other machines or compressor malfunctions

Air Turbine Tools® Breakage Alarm - Detect Malfunctions and Prevent Damage to your Machine & Parts

Detect Compressor Failure and Supply Problems

Monitoring air flow against the recorded baseline assures you consistent operation through your programs and mitigates risk to your work in process and machine.