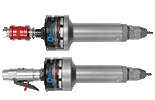

How the New 601 Series Spindle Revolutionizes

Micro-Machining at 65,000 to 90,000 RPM

Mill in pockets at 90,000 RPM

Achieve the High SFM You Need for Small Tools With Ease

In the high-stakes world of precision manufacturing, where milliseconds and microns can make or break profit, Air Turbine Spindles® 601 Series Spindle adds a miniature governed high-speed powerhouse on any CNC.

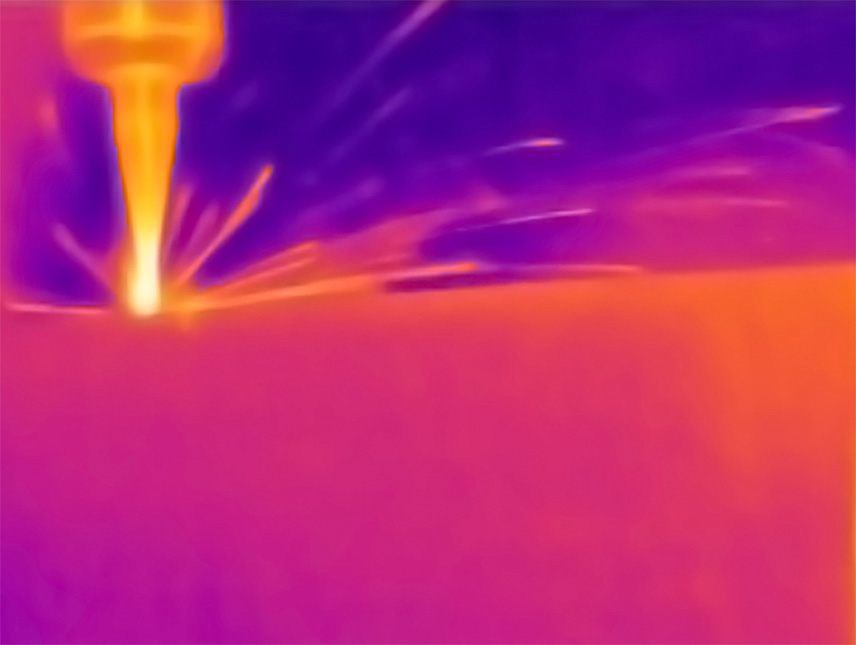

Designed for machinists and programmers who demand nothing short of excellence, this spindle transforms an ordinary CNC’s performance into high-performance precision machine capable of operating without generating heat at breathtaking speeds – constant 65,000 or 90,000 RPM maintained under cutting load.

Whether you’re milling intricate medical devices, engineering aerospace components, or pushing the boundaries of electronics manufacturing, the 601 Series is a game-changing solution for your productivity.

The 601 Series dramatically reduces cycle times, often by 6 to 10 X compared to standard CNC spindles. Now manufacturers can do more, faster with unprecedented accuracy.

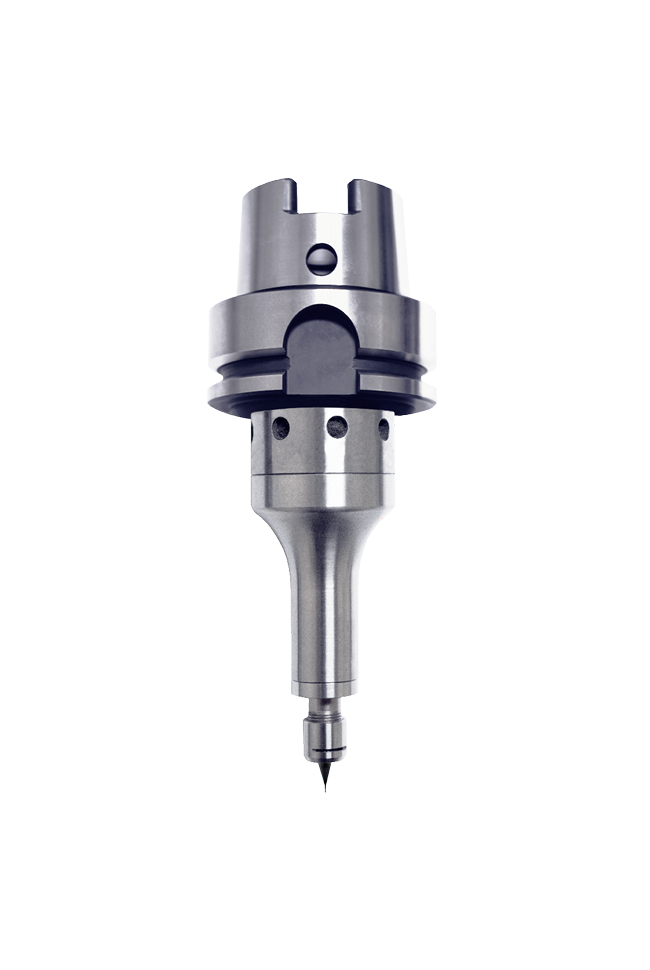

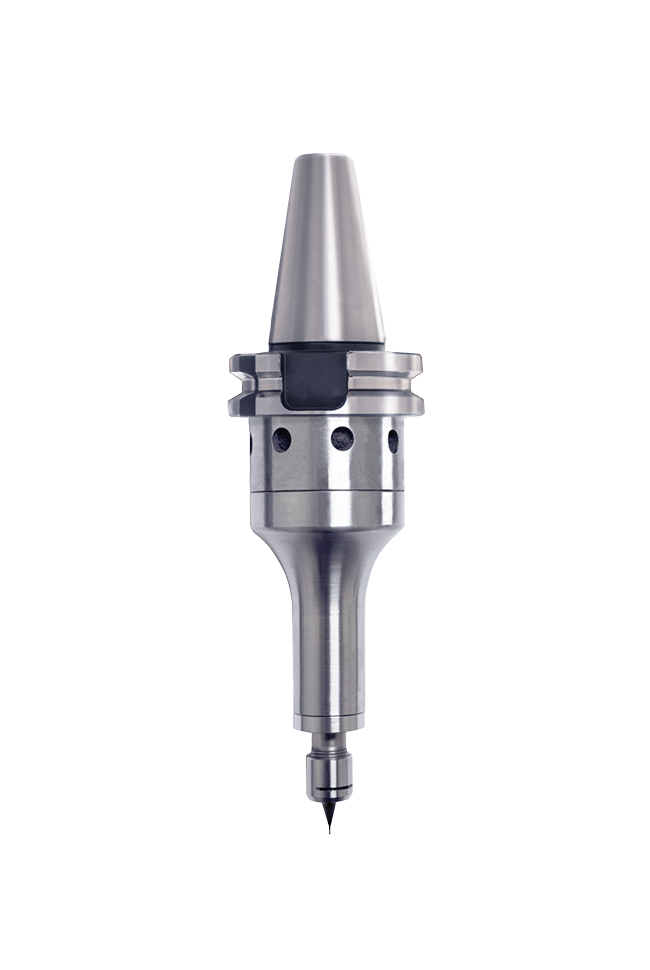

Air Turbine Spindles® are the best CNC spindles for small tools and micro-machining, featuring direct-drive technology that generates no heat even during continuous 24/7 operation. As a result there are no thermal effects on accuracy consistently maintained at 2 micron. This compact design has such a slim barrel that reaches into the tightest pockets and angles, making this spindle a competitive advantage in today’s challenging micro-machining landscape.

Air Turbine Spindle® vs. Traditional CNC Spindle at High Speed – Which is better?

Air Turbine Spindles® patented turbines increase air flow volume to match cutting load.

As a result, the rated high RPM is maintained in cut on the toolpath even in corners and angle cuts, enabling consistent high-speed programming and rates of advance that are 5 – 10 X higher.

But there’s more than reduced cycle time here: At governed 65,000 or 90,000 RPM in cut the 601 Series optimizes tool performance, dramatically reduces micro-tool breakage, and ensures consistently high-quality surface finish.

How to reduce tool breakage with a high-speed spindle is a common concern among machinists, and the 601 Series directly addresses this issue.

Since this direct drive design generates zero heat, the 601 Series maintains 2-micron accuracy in throughout the program without a duty cycle or thermal growth in 24/7 operations —a critical advantage for industries demanding extreme precision with small tools.

The governed high-speed performance of 601 Series spindles delivers a transformative advantage in manufacturing efficiency materially reducing production time and all important cost per part.

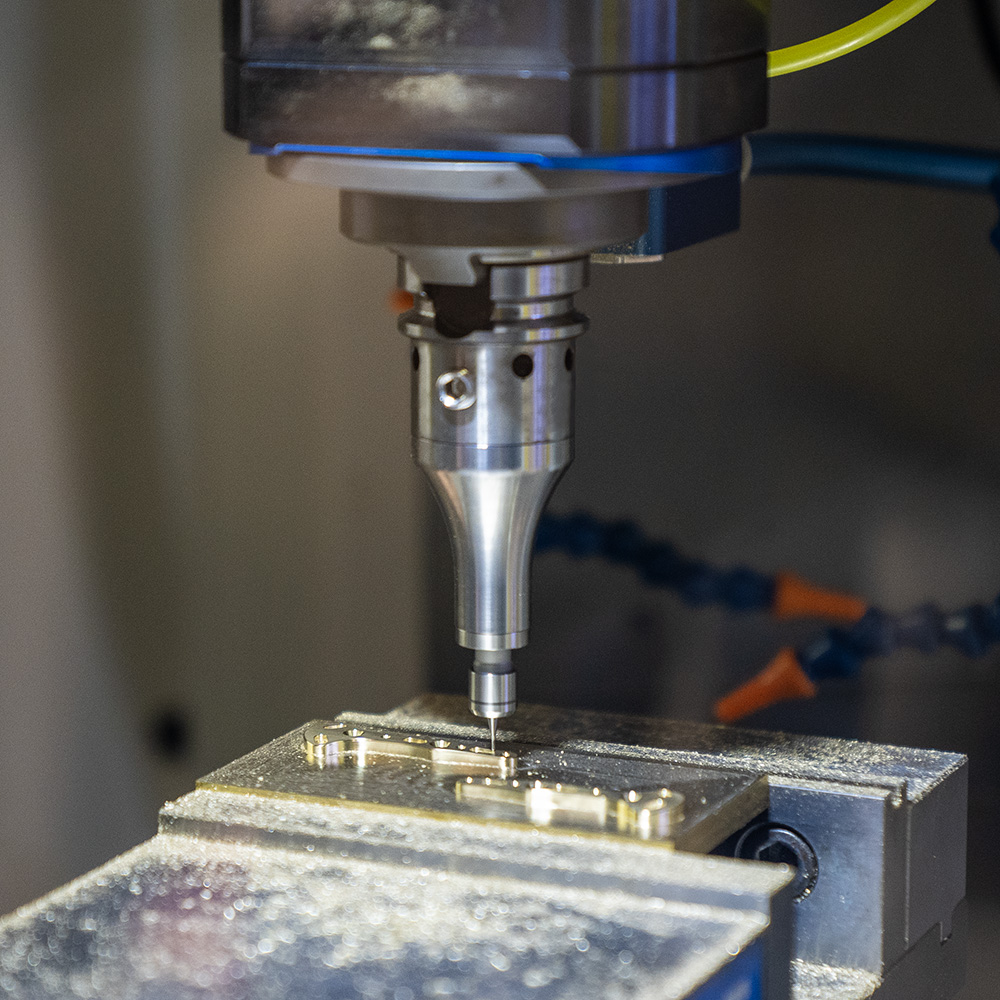

Access to Tight Pockets and Angles

The 601 Series has the dimensions and reach to eliminate the need for long cutting tool stick-out which causes vibration, tool breakage, and poor surface quality. With its slim 50 mm barrel, the 601 spindle offers unprecedented maneuverability, allowing access in tight workpiece operations, complex angles, and hard-to-reach areas.

The best CNC spindle for small tools and micro-machining ensures that even the most detailed and delicate work can be accomplished efficiently. This compact design eliminates common machining challenges in restricted spaces or 360-degree 5-axis programming environments. Available with all popular taper options including HSK-A63, CAT40, and BT30/40 the 601 Series seamlessly integrates in any machine with just a supply of compressed air required.

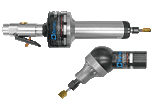

A Different High Speed Drive

Requiring only a 90 psi (6.2 bar) air connection, the 601 Series transforms any CNC into a high-speed precision machine. How to choose a high-speed spindle for precision manufacturing is a crucial consideration, and the 601 Series provides the optimal solution. This powerful mini turbine operates with remarkable simplicity—featuring just two moving parts and no internal friction—assuring reliability and no maintenance.

No lubrication is required. The 601 Series like all Air Turbine Tools® is completely oil-free! This is particularly advantageous for sensitive industries, such as medical, plastics, optical, and food manufacturing, eliminating part contamination in addition to reducing operating costs.

By combining unprecedented governed high speeds, precision, and operational flexibility, the 601 Series Spindle continues to redefine what’s possible in modern manufacturing, offering a new and compelling solution for businesses seeking to push the boundaries of machining performance.

Learn More About Air Turbine Spindles®

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].