Speeds from Governed 25,000 RPM to 90,000 RPM

Up to 1.4 HP (1.03 kW) Power to Maintain Speed in Cut

Up to 1.4 HP (1.03 kW) Power to Maintain Speed in Cut

Direct Drive

There are only two moving parts with Air Turbine Tools®

- Proprietary governed turbines

- Air-cooled steel grease packed bearings

This results in no heat, no duty cycle, and great durability. The governor control delivers power on demand and minimizes air consumption. Power on demand to 1.4 HP (1.03 kW) with Air Turbine Spindles® patented double turbines.

Our constant high speed in cut will improve your surface finishes and increase tool life while reducing production time.

High Speed & Power

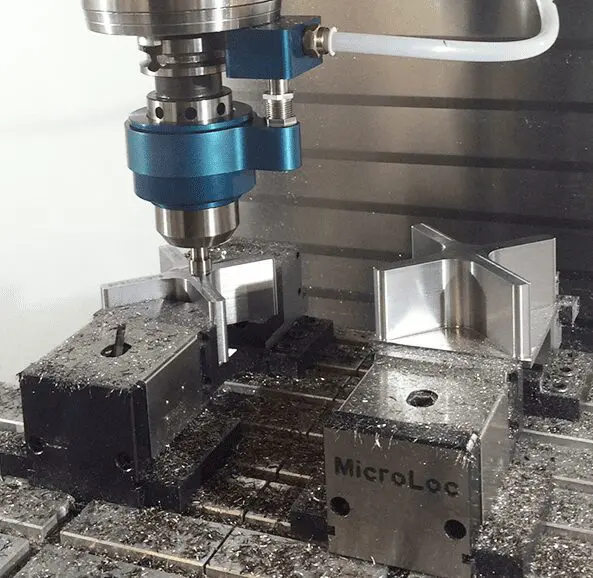

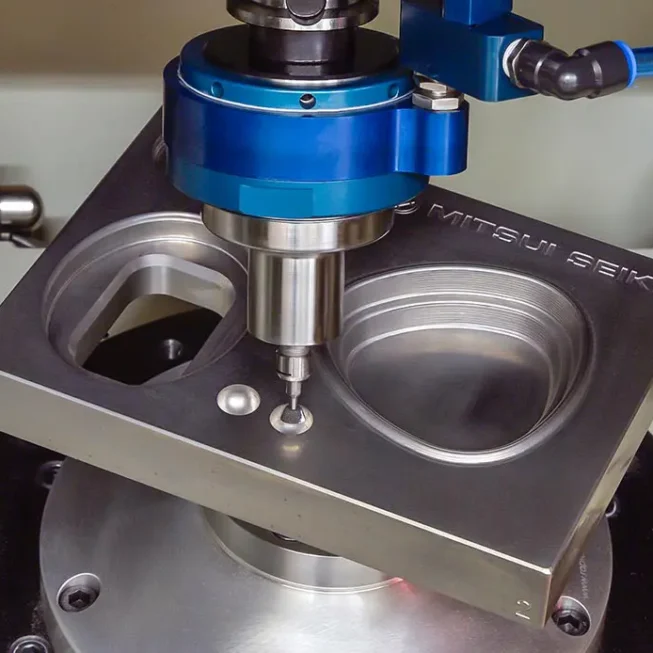

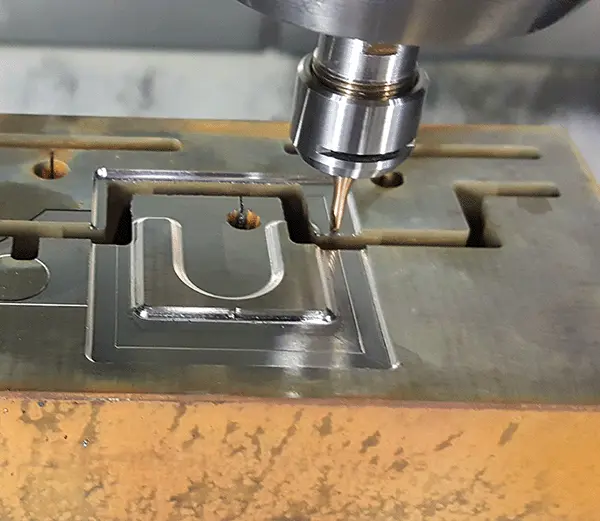

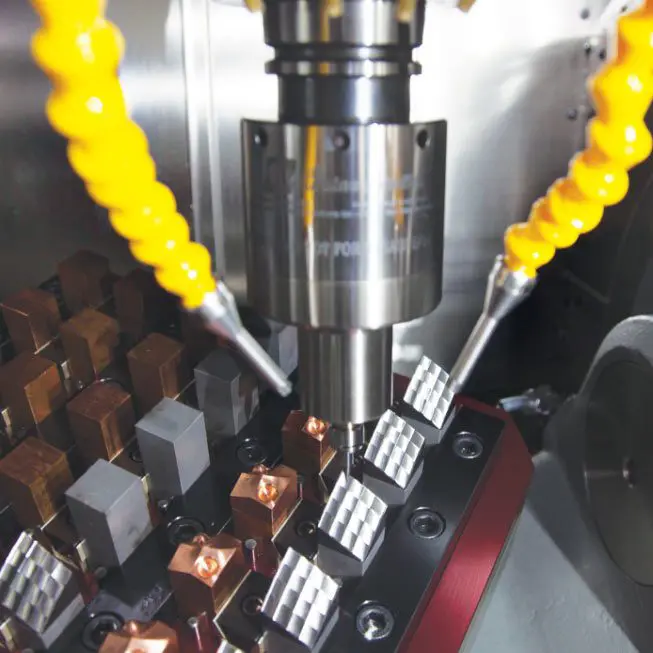

Air Turbine Spindles® generate no heat, low vibration, and operate reliably with no duty cycle. Mill at 24/7 with speeds at governed 25,000 – 90,000 RPM with power available to 1.4 HP (1.03 kW). Constant high speed on the tool path makes Air Turbine Spindles® ideal for precision micro-machining, milling, slotting, drilling and profiling with small tools. Reduce wear on your CNC spindle and save on repair costs.

Just connect compressed air, enter an M Code to mill at 400”/min (10,000 mm/min) with 2μ accuracy.

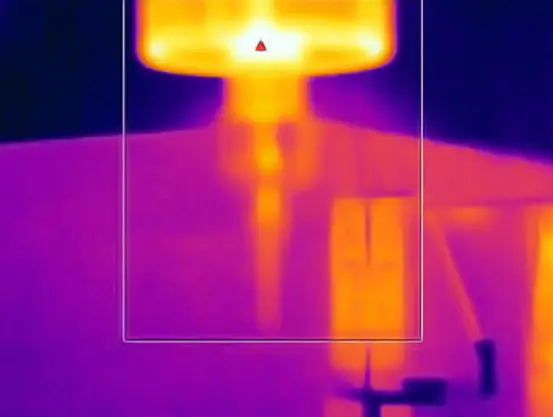

No Thermal Expansion

Air Turbine Spindles® generate no heat, low vibration and operate reliably with no duty cycle in 24/7 non-stop operations. The key difference from speeders or electric spindles is that there are no gears, high-frequency brushes, or vanes to burn out. No thermal expansion in Air Turbine Spindles® assures precision at 2µ and reliability.

Speeds and Feeds

The Hard Math

Feed and speed rates need to be determined to optimize machining time, surface finish, and tool life. Speeds and feeds along with required horsepower can be calculated using the machinist’s handbook and a series of formulas.

Information in the Machinists Handbook assumes production speeds: i.e. an average tool life of fewer than two hours.

Air Turbine Spindles®

vs. Coolant Driven Spindles

You’ll get high speed that does not drop on engagement with powerful governed Air Turbine Spindles®.

Check out the comparison to coolant driven spindles

Air Turbine Spindles®

vs. Speeders

Air Turbine Spindles® rated high speed does not drop on tool engagement like “speeders”.

Our turbines have no vibrating gears and do not have High-Frequency brushes like electro spindles. As a result, Air Turbine Spindles® do not get hot, burn out, or thermally expand like speeders.

Try our direct drives with only 2 moving parts – you’ll find they generate no heat and are durable.

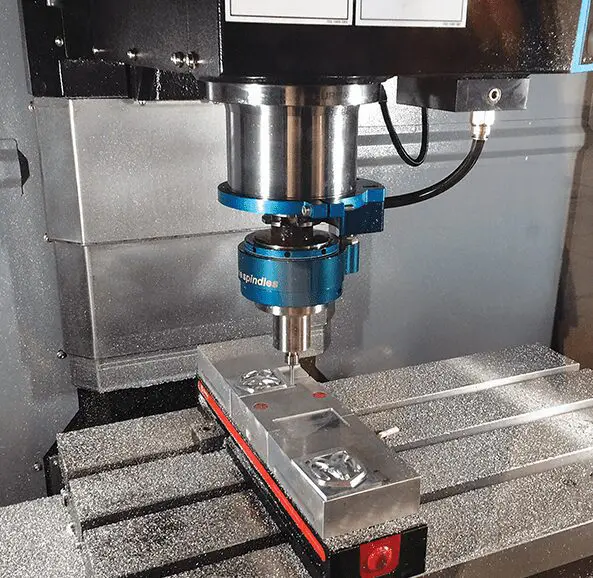

Retrofit any CNC

Air Turbine Spindles® retrofit any CNC, including but not limited too – Haas, Fanuc Robodrill, Hermle, Hurco, DMG Mori, Okuma, Mazak, Hwacheon, and Brother.

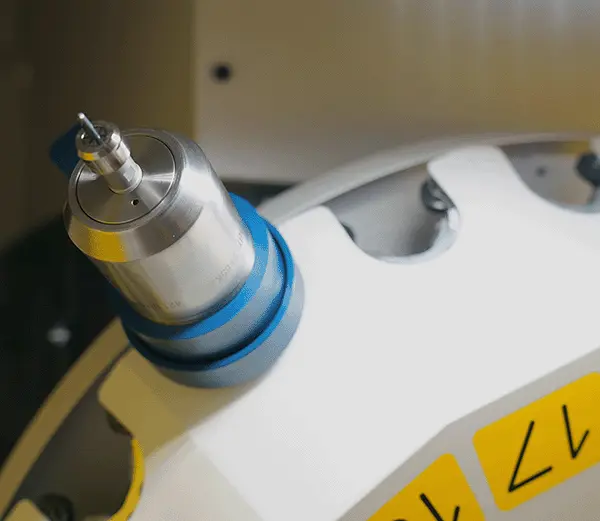

Installation Guides and Mounting Options

Get started with your Air Turbine Spindle® today with our installation guides.

Mounting options include straight shank, integrated shank, and Toolchanger Mounting Assembly.

Spindle Series

Find the right Air Turbine Spindle® for your application.

Service & Support

Support is always available from our technical team in the USA, Germany and Mexico. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].