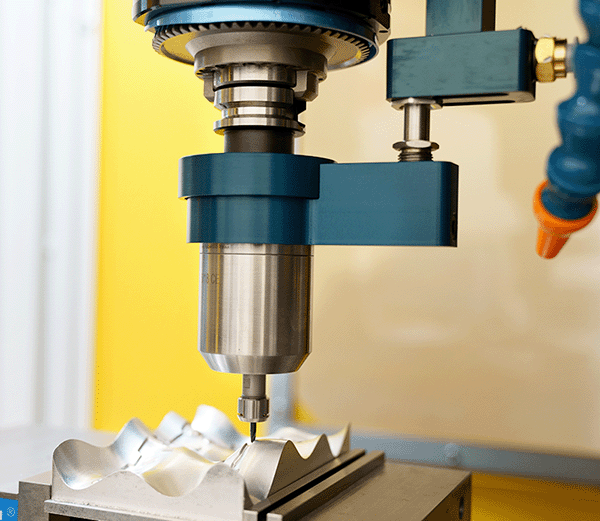

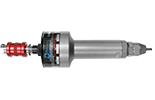

Input Air Turbine Spindles® governed speeds from 25,000 to 90,000RPM and you will see the scale of savings these direct drive spindles can achieve in your application.

Methodology

Feed and Speed rates need to be determined to optimize machining time, surface finish, and tool life. Speeds and Feeds along with required horsepower can be calculated using the machinist’s handbook and a series of formulas. Information in the Machinists Handbook assumes production speeds: i.e. an average tool life of fewer than two hours.

Production speeds state the maximum production for the cost of tooling, though they are sometimes impractical for the small jobs done at the machine shop. However, calculated speed and feed rates do give a useful reference in determining what rates should be used for our purposes. The following demonstrates how to calculate Speeds and Feeds for a surface milling or slotting operation.

Comparison of Cutting Speed with a 1.5mm End Mill

Standard Machine Spindle at 12,000 rpm = 2.22”/min (56.5 mm/min) advance

Air Turbine Spindles® 625 Series at constant 50,000 rpm = 9.28”/min (235.6 mm/min) advance

Your Cutting Speed is increased 4.2x with Air Turbine Spindles®!

In addition to reducing cycle time, the accuracy of the cutting tool is improved and its life extended

Cutting Speed = (D × π × Spindle Speed )/1000

Machinist Handbook Values

Surface Feet per Minute

Also called Cutter speed. Speed of a point on the outside diameter of the tool. Value depends on the material.

Feed Per Tooth

Also called Chip Load. Amount of stock removed by each tooth during a single revolution. Value depends on stock material, tool size, and tool material.

Horse Power Factor

The number used to calculate power requirement. Value depends on the material.

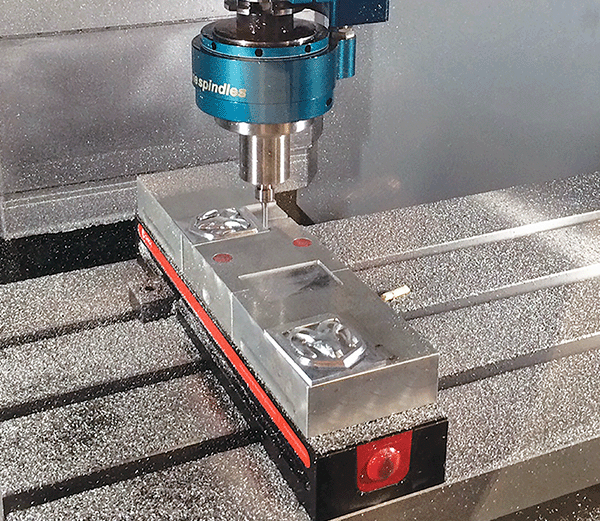

Air Turbine Spindle® vs Fanuc Robodrill Main Spindle Cycle Times Cut in Half

C/T Reduced by 25 Minutes with 50,000 rpm! Pocketing Brass with Air Turbine Spindles®

Application Information

►

►

►

Related Videos

Restoring Antique Pocket Watches into Wrist Watches with Vortic Watches and Air Turbine Tools®

3D Surfacing at 40,000 RPM Cut Cycle Times by 4x

Testimony from Ken Stauver from KS Analytical Systems

Cycle Times Cut Dramatically! Drilling Aluminum at 50,000 rpm on Robodrill