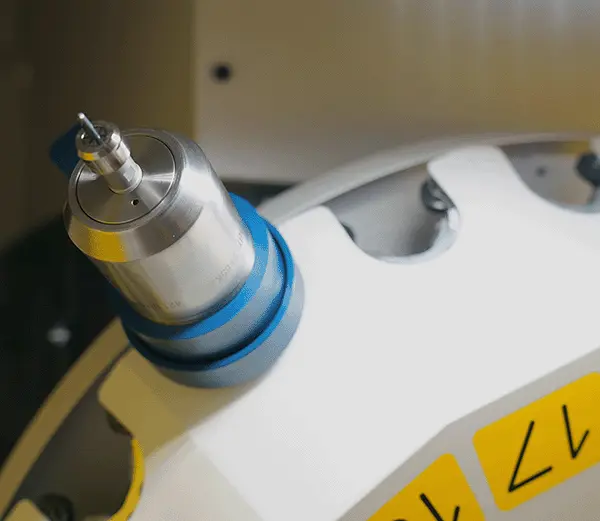

Optimal Spindle for Each Tool

√ = Optimal

∞ = Acceptable

! = Dependent upon cutting conditions

× = Not recommended for use

602

602

|

625 / 625X

625 / 625X

|

650 / 650X

650 / 650X

|

|

|---|---|---|---|

| Drill | |||

| Ø 0.004 - 0.012“ (0.1 - 0.3mm) | √ | √ | √ |

| Ø 0.012 - 0.020” (0.3 - 0.5mm) | ∞ | √ | √ |

| Ø 0.020 - 0.039” (0.5 - 1.0mm) | ! | √ | √ |

| Ø 0.039 - 0.059” (1.0 - 1.5mm) | × | ∞ | √ |

| Ø 0.059 - 0.079” (1.5 - 2.0mm) | × | ! | √ |

| Endmill | |||

| 602 | 625 / 625X | 650 / 650X | |

| Ø 0.004 - 0.039” (0.1 - 1.0mm) | √ | √ | √ |

| Ø 0.039 - 0.079” (1.0 - 2.0mm) | ∞ | √ | √ |

| Ø 0.079 - 0.138” (2.0 - 3.5mm) | ! | √ | √ |

| Ø 0.138 - 0.197” (3.5 - 5.0mm) | × | ∞ | √ |

| Ø 0.197 - 0.236” (5.0 - 6.0mm) | × | ! | √ |

| Jig Grinding | √ | √ | √ |

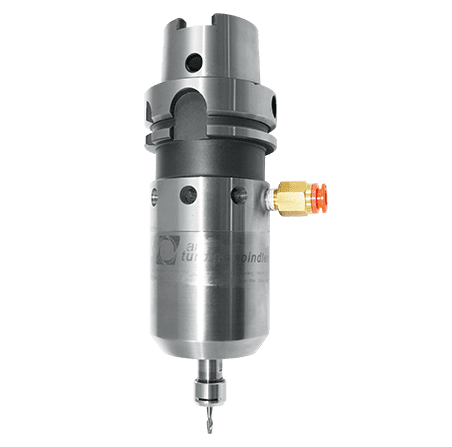

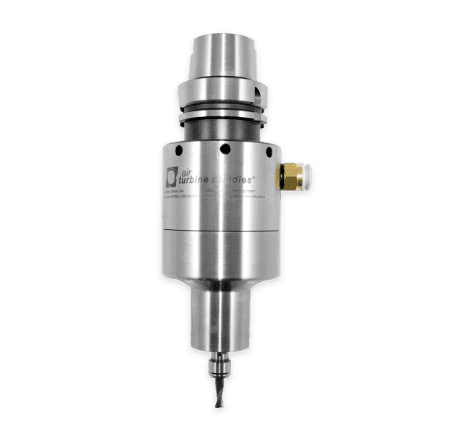

| Specifications | |||

| Governed Speed - rpm | 602 |

625 / 625X |

650 / 650X |

| Power Rating - hp (kw) | 0.15 - 0.20 |

0.40 - 0.78 |

0.80 - 1.40 |

| T.I.R. at Nose | Less than 2m | ||

| Collet Range | 0.5mm - 7mm | ||

| Air Pressure | Less than 90 psi (6.2 Bar) (0.62 MPa) | ||

| Air Flow | 5 - 40 CFM (2.36 - 18.89 L/s) [ANR] | ||

*Due to its governed high speed and power the 602 90,000 rpm is for use only with micro end mills in special applications

The above table is a general guideline. Each application is different. Please contact us at [email protected] to discuss your application or complete our applications questionnaire.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].