Automatic Tool Changer Products

CNC Spindle Accessories

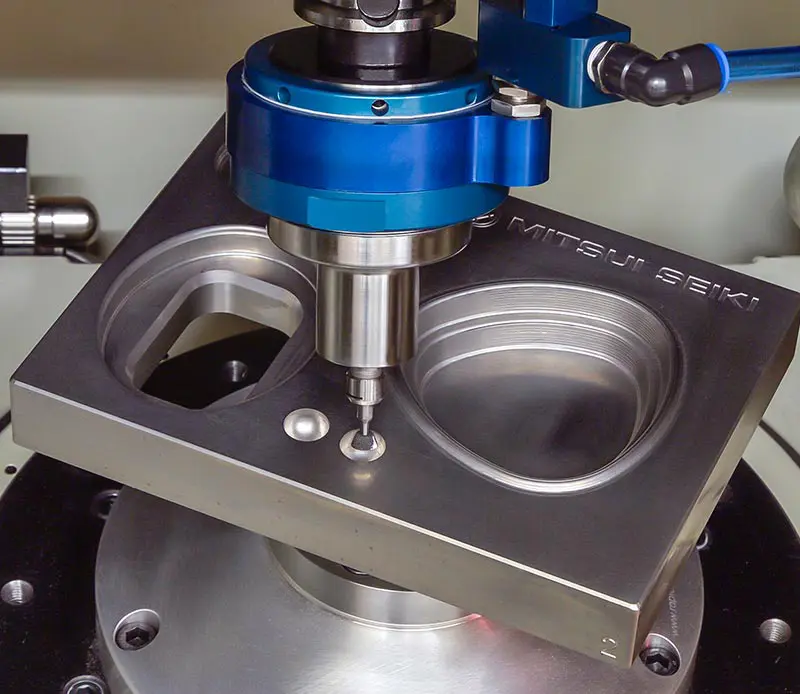

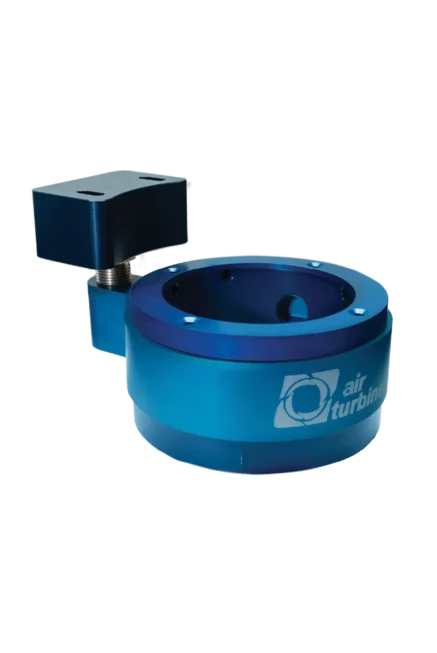

Automatically load Air Turbine Spindles® in CNC machines with our patented wrap-around Tool Changer Mounting Assembly (TMA). This option allows CNC tool changers to automatically load/unload our family of high-speed precision spindles using a proprietary collar system and mounting block or ring around the CNC spindle integrated to the right side of the CNC spindle in minutes.

Mounting blocks or rings compatible with Haas, Hurco, Doosan, Robodrill, Hardinge, DMG, Brother, Okuma, and all other CNC’s are available. We are accustomed to developing custom solutions to enable auto tool change on any CNC. A Universal Block can be provided for drilling your CNC screw positions. Installation Kits are available. The TMA block remains on the CNC spindle for normal tool changes, even if not using the Air Turbine Spindles™ as it will not interfere when using the main spindle.

TMA Assembly Includes

- Mounting block or ring assembly

- Spindle manifold collar with adjustable height connector to block

Note: Air Turbine Spindles® TMA option is not required on VMC’s where an air blast line or coolant channel can be used to supply sufficient CFM / L/s airflow volume.

Center air feed to the selectable rear air inlet on your Air Turbine Spindle® can be used if the airline / coolant channel has 1/4” / 6.5 mm internal diameter for 602/625 models. Not suitable for 625X/650(X)/660 CAT/DIN/BT models due to internal diameter requirements for airflow. All HSK spindles can be used with center air feed if the air supply line has sufficient ID. If used for air supply, the coolant channel and connector tube must be purged and clean before air is induced.

$ 1,500.00

| TMA (Block + Collar) | |

|---|---|

| Model | Part Numbers |

| 602 – Universal 40 Taper** | 36227 |

| 602 – Universal 30 Taper** | 36276 |

| 602 – Haas 40 Taper | 36218 |

| 602 – Haas 30 Taper | 36278 |

| 602 – Fadal 40 Taper | 36221 |

| 602 – Hurco VM / VMX SERIES | 36284 |

| 625(X) – Universal 40 Taper** | 36228 |

| 625(X) – Universal 30 Taper** | 36277 |

| 625(X) – Haas 40 Taper | 36219 |

| 625(X) – Haas 30 Taper | 36279 |

| 625(X) – Fadal 40 Taper | 36222 |

| 625(X) – Fadal 30 Taper | 36281 |

| 625(X) – Hurco VM / VMX SERIES | 36285 |

| 650(X) / 660(X) – Universal 40 Taper** | 36229 |

| 650(X) / 660(X) – Universal 50 Taper** | 36290 |

| 650(X) / 660(X) – Haas 40 Taper | 36220 |

| 650(X) / 660(X) – Haas 50 Taper | 36291 |

| 650(X) / 660(X) – Fadal 40 Taper | 36223 |

| 650(X) / 660(X) – Fadal 50 Taper | 36292 |

| 650(X) / 660(X) – Hurco VM / VMX SERIES | 36286 |

**Drilling of mounting block holes required on Universal Blocks

| Block Only | |

|---|---|

| Model | Part Numbers |

| Haas Mounting Block | 36210 |

| Fadal Mounting Block | 36211 |

| Universal Mounting Block** | 36213 |

**Drilling of mounting block holes required on Universal Blocks

| Collar Only | |

|---|---|

| Model | Part Numbers |

| 602 Collar 40 Taper | 36215 |

| 625(X) Collar 40 Taper | 36216 |

| 650(X) / 660(X) Collar 40 Taper | 36217 |

Videos

TMA Installation on Haas Machine with Air Turbine Spindles®

Auto Tool Change your Air Turbine Spindle® with the Tool Changer Mounting Assembly

Hurco Autochange by Air Turbine Spindles®

Autochange on FANUC Robodrill with Air Turbine Spindles® 625XDT and 602DT

Frequently Asked Questions

An Automatic Tool Changer (ATC) is a device that allows a machine to quickly and automatically change tools while in operation.

The ATC is a motorized device incorporated into the machine and capable of quickly exchanging tools. The ATC is connected to a control unit that allows the operator to select the tools that need to be used. It will automatically move to the selected tool and mount it to the machine.

An ATC offers many benefits to a machine shop. The first benefit is increased efficiency. By using an ATC device, the machine operator can select the necessary tools without having to manually change the tool each time.

By providing a way to perform an automatic tool change, the operator is able to complete more tasks in a shorter amount of time. Additionally, the ATC also reduces the risk of operator error by eliminating the need for manual tool changes. This results in more consistent and accurate machining results.

There are a variety of different tool holder types that are compatible with automatic tool changing devices these include CAT, DIN, BT, HSK. Unless you have a CNC machine equipped with air thru the spindle capabilities you may require an additional attachment we call a Tool Changer Mounting Assembly (TMA).

The TMA is easily retrofitted to most CNC machines in just a few minutes.

Air Turbine Spindles® are compatible with a variety of machines, including CNC lathes, milling machines, and drilling machines.

An ATC spindle consists of a motor, a tool changer, a control unit, and a spindle.

‣ The motor powers the tool changing device

‣ The tool changer exchanges the tools.

‣ The control unit selects the tools that need to be used.

‣ The automatic tool changer is responsible for mounting the tools to the spindle of the machine.

Like Air Turbine Spindles® they require no maintenance for the everyday operation. The operator should ensure clean dry air is used and regularly inspect the filter regulator extractor to empty any accumulated moisture, oil or debris.