Case Study: Cutting CNC Cycle Time By Over 80%

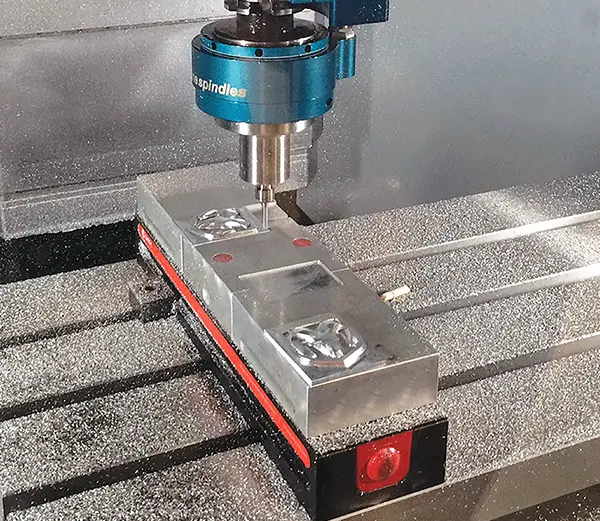

In a recent side-by-side study, AW2024/31355 aluminum was milled using both a standard Haas 8,000 RPM CNC spindle and the Air Turbine Tools® 650 spindle series, each with a ball nose tool. The cycle time…