Unmanned Vehicle Bonded Carbon Fiber Wing Machining

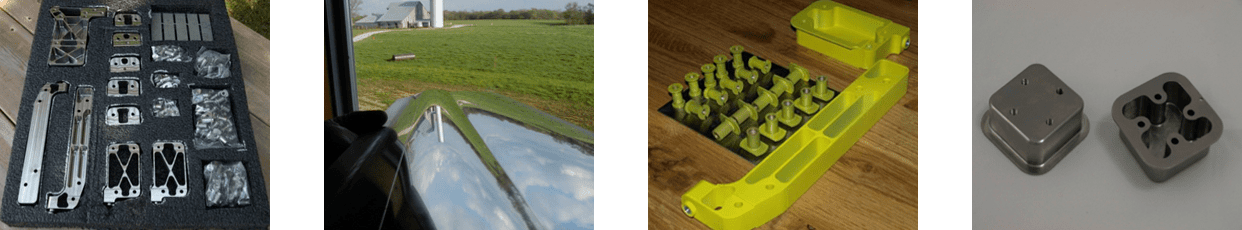

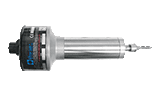

Mr. Peter Bowman is in charge of part fabrication at a successful manufacturer of aerospace components, Flying S Inc, located in Palestine, Illinois. Flying S Inc was founded by Mr. David Shaw with the motto: “Designing Elegant Solutions for Aerospace Problems”. A selection of Flying S Inc’s products are pictured below:

Mr. Bowman encounters a machining problem:

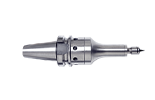

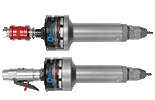

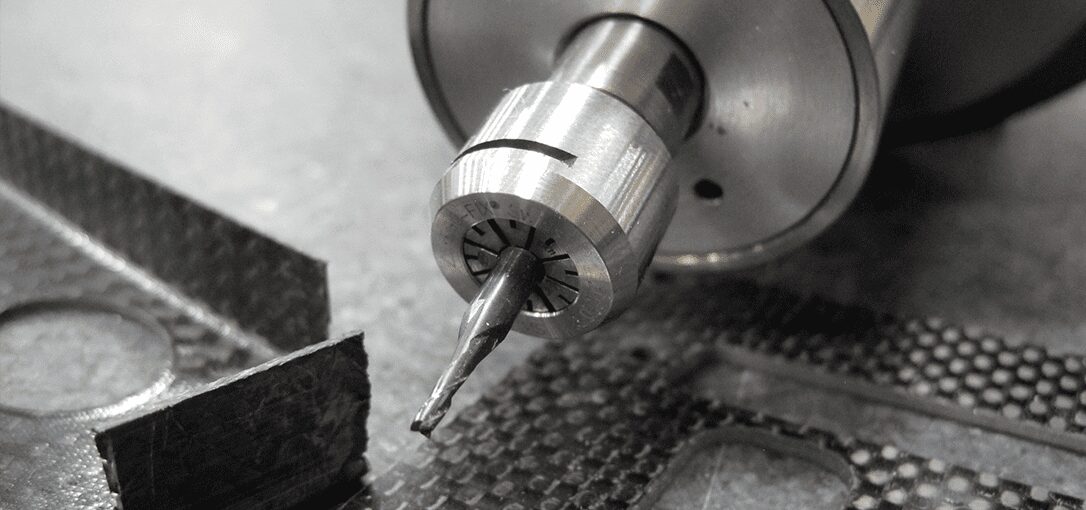

Mr. Bowman states: “We came across a project that required us to cut carbon fiber that had been bonded to a proprietary, hardened material. Cutting this bonded carbon fiber part was difficult because we have to use a 0.0625 end mill in a way that didn’t create burrs and could be done at production speeds.”

“While making test cuts, we found that our fastest spindle at the time was destroying the part during the cutting process! Bottom line: We couldn’t make the parts!”, says Mr. Bowman.

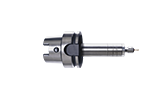

“Flying S was looking for an economical solution that could turn a 1/16″ or less diameter end mill at the speeds we needed for this particular application. We also needed to retain the ability to tool change on our carbon-cutting CNC for the other parts that we’re trimming in production.”

Vincennes University HTEC Assists Flying S Inc

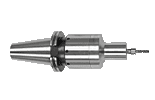

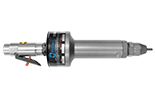

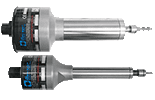

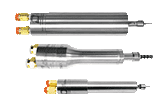

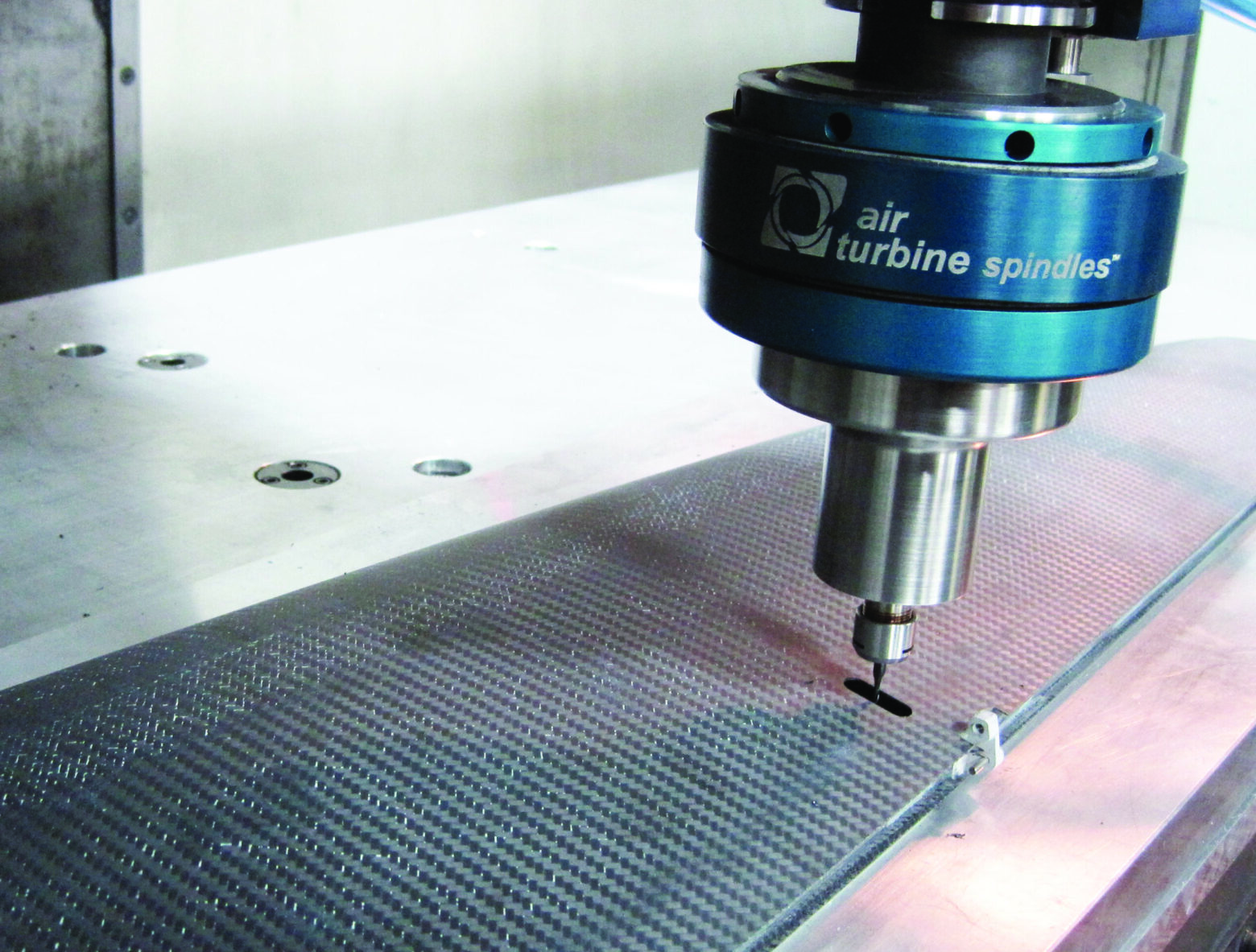

“With some of these issues fresh in mind, I attended some training at Vincennes University Technical Center and noticed an air spindle attachment mounted to one of their Haas machines. I immediately asked for more information. It was a 40,000 RPM 650 series spindles manufactured by Air Turbine Spindles® with automatic spindle loading capability.”

“It was exactly what I was looking for.”

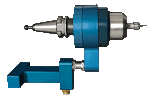

“Their TMA feature, integrating Air Turbine Spindles®, means the program is not interrupted when we switch to the high-speed work. Plus there’s no duty cycle and their governor on these spindles so we can keep the tool cutting at high speed.”

The High-Speed Solution

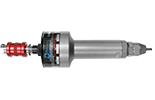

Mr. Bowman of Flying S Inc continues: “Not long after that, we had our own constant speed double turbine 40,000 RPM 650X made in the USA by Air Turbine Spindles® on our Haas machine back at the plant.”

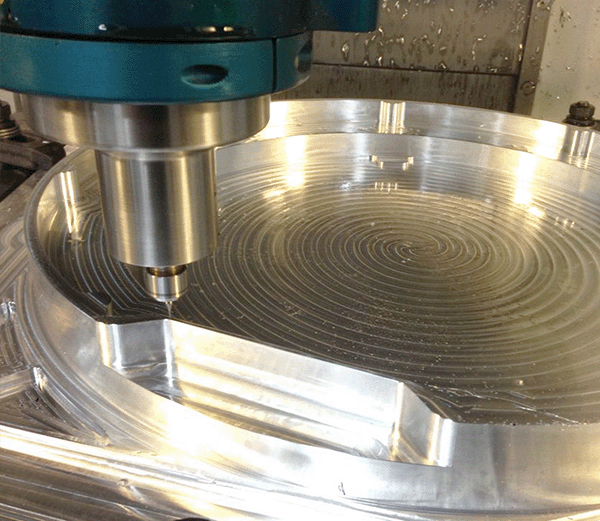

“For a fairly economical price, we were able to take our versatile 7,500 rpm Haas VF-6 CNC machine and upgrade it to be able to perform a very high precision intricate job at 40,000 RPM.”

“Our carbon fiber and hardened steel parts part project proved to be no problem with the governed high RPM. The 650 is quiet and leaves our parts burr and oil-free.”

Mr. Bowman adds: “The tool changing Assembly enable our Haas CNC to load our 650X from the magazine and run completely unattended in full production. That feature to integrate Air Turbine Spindles™ is saving a huge amount of man-hours on our jobs.”

“Our programmers have greatly enjoyed this high-speed spindle capability and rely on its abilities as we’ve moved forward on other Flying S Inc projects.”

Our Thanks to The Flying S Team – In Palestine, Illinois.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].