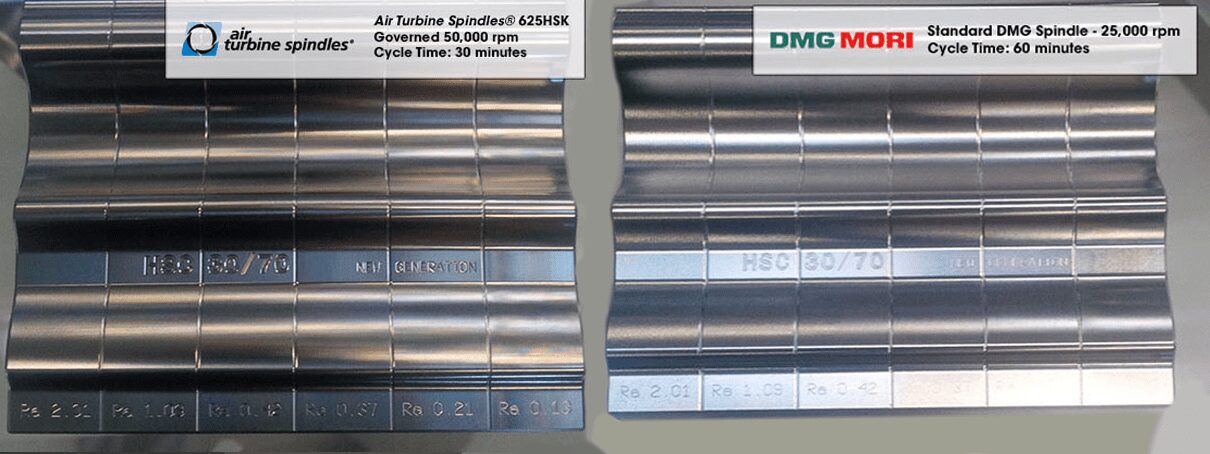

Comparison of Cycle Time and the Surface Quality

Standard Spindle v. Air Turbine Spindles® 50% Time Reduction

Cycle Time Comparison

Any CNC becomes a high-speed machine in minutes with Air Turbine Spindles®.

The quality at Ra 0,13mµ and precision were indistinguishable between the 25,000 RPM DMG HSC 55 spindle.

Load your Air Turbine Spindles® automatically from any CNC magazine into your main spindle. Clean dry compressed air is induced through a clean airline, or an optional patented mounting block and collar, for seamless integration in your program. No manual hook up required unless preferred.

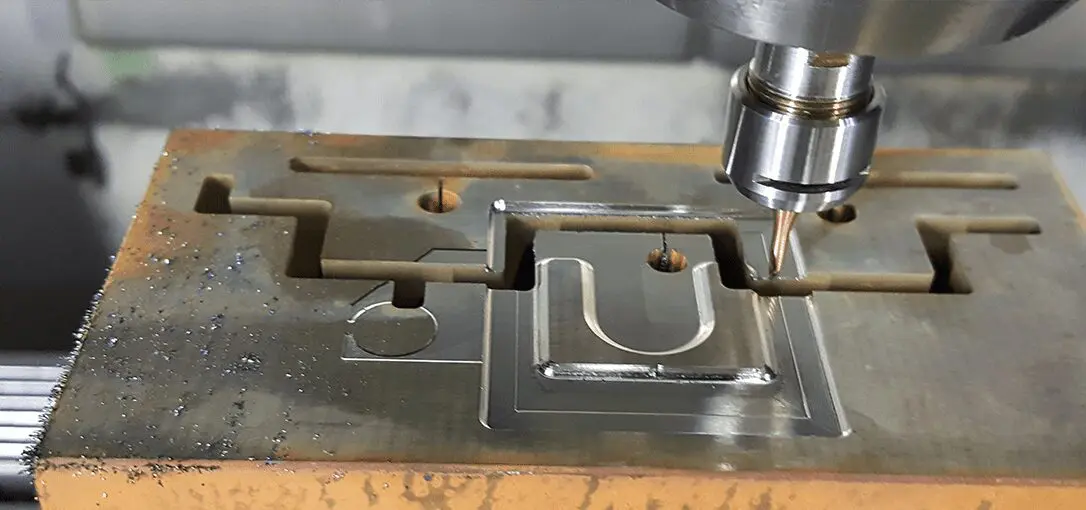

CNC Spindle Milling Steel at 5000 mm/min on DMG Mori at 50,000 RPM and 0.76 HP

Maintain constant high speed on the tool path at 25,000 to 90,000 RPM with power to 1.4 HP (1.04 kW) – You keep constant high rotational speed in angles and hard materials. This is because Air Turbine Spindles® patented governor increases airflow in the turbine in proportion to the load. Reliable with low vibration, no heat, and no duty cycle for 24/7 milling.

Our direct drives have only 2 moving parts – our proprietary turbine and ceramic bearings, and the bearings are cooled by turbine airflow. No High-frequency brushes, no gears to burn up, no control system.

Just connect to 90 psi / 6.2 bar and high-speed Air Turbine Spindles® and mill, drill, and accelerate your feeds with no duty cycle. No control system or lubrication required.

For European Clients, Please Contact:

Mr. Wolfgang Pfahler

Thanks to DMG Mori for this comparison test at DMG Mori Seiki’s Geretstreid Showroom near Munich.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].