How Air Turbine Tools® Cut CNC Cycle Time By Over 80% with High-Speed Machining

Machining aluminum alloys such as AW2024/31355 with standard CNC spindles can be both time-consuming and costly. For example, a typical 8,000 RPM spindle, commonly found in many Haas CNC machines, may take up to two hours to machine a contoured part with a ball nose tool. These extended cycle times not only reduce throughput but can also compromise surface finish quality and drive up overall production costs.

Dramatic Insert Cost Reduction

Mr. Doug Holt saw Air Turbines governed 40,000 RPM 650CAT match the same D.O.C and feed rates of the speeder but there was a big difference. While the speeder took 3 - 4 inserts to finish one engraving sequence, Air Turbine Spindles® 650 was able to use the same insert for 4 sequences in a row.

Test Comparison: CNC Main Spindle v. Air Turbine Spindles®

More than 100% Improvement in cycle time. See the difference yourself when milling the same part from aluminum with the HAAS CNC Main Spindle and the 625 Air Turbine Spindle Series®.

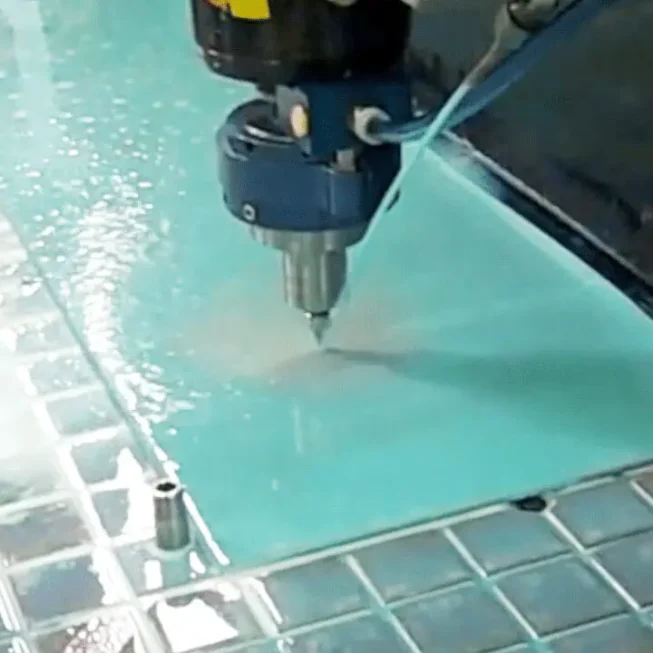

Unmanned Vehicle Bonded Carbon Fiber Wing Machining

How Mr. Peter Bowman from Flying S was able to manufacture a product he previously could not with Air Turbine Spindles®.

Milling Steel on DMG Mori HSC55 in Munich, DE

Comparison of cycle time and the surface quality. Standard Spindle v. Air Turbine Spindles® - 50% time reduction.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].