More than 100% Improvement in Cycle Time

88 Minutes v.s. 35 Minutes

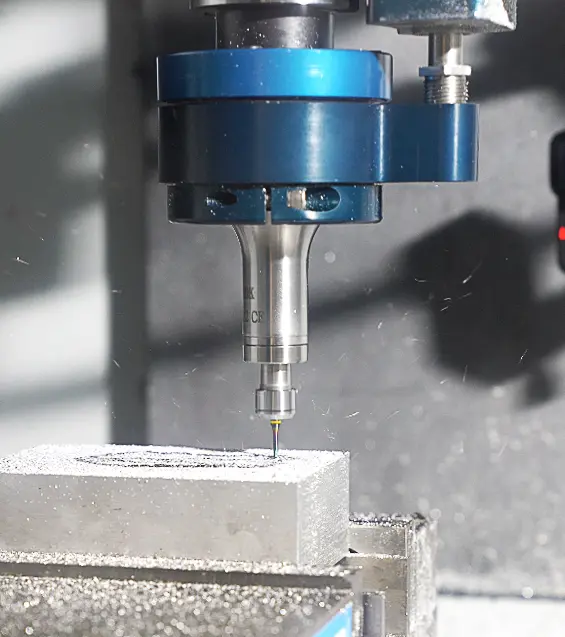

Haas CNC Main Spindle v. The Air Turbine CNC Spindle

How was the more then 100% improvement in cycle time achieved?

Air Turbine Spindles® are governor-controlled. Airflow increases if the rotational speed slows, maintaining the high speed under load when you start cutting – even on angles and hard materials. The constant high speed while in cut will improve your surface finishes and increase tool life while reducing production time.

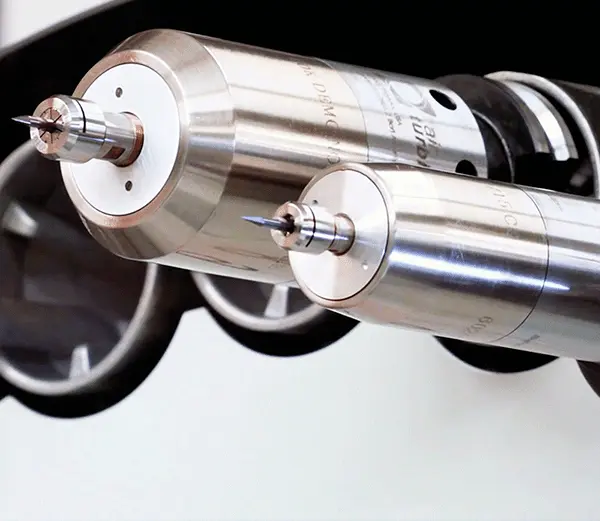

No need for downtime to install our constant high speed direct drive spindles. Automatic loading from any CNC magazine is available.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].