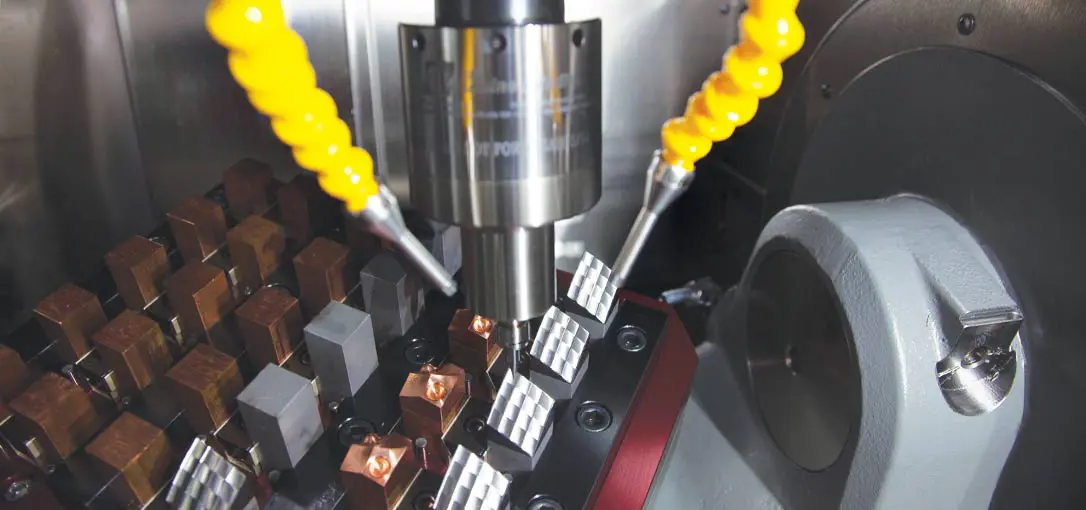

Revolutionary High Speed Precision Technology that Redefines Performance Standards.

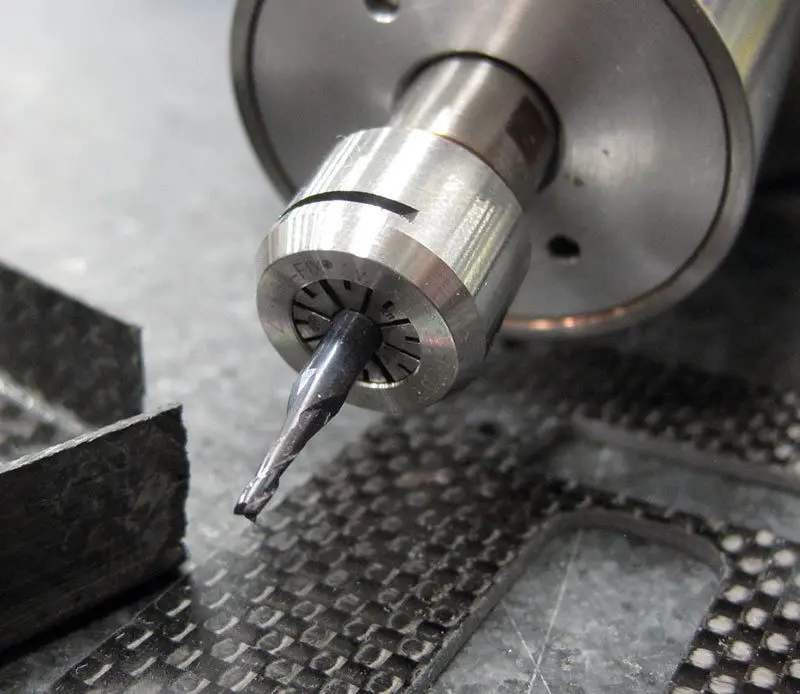

Direct Drive

There are only two moving parts:

- Proprietary governed turbines

- Air-cooled steel grease packed bearings

Fewer moving parts mean low friction, no heat, low vibration and fewer repairs. No gears vanes, or brushes to burn up. There is no lubrication or maintenance required.

'O' Ring Control of Air Flow

The patented ‘O’ ring controlled governor in our turbines deliver power on demand by increasing the flow of air under load to keep the speed high under cutting load.

The ‘O’ ring delivers efficient power on demand staying close to speed. Mill tool steel, kevlar – maintaining high peripheral cutting speed in corners and pockets.

The governor also regulates airflow to match cutting load, minimizing air consumption.

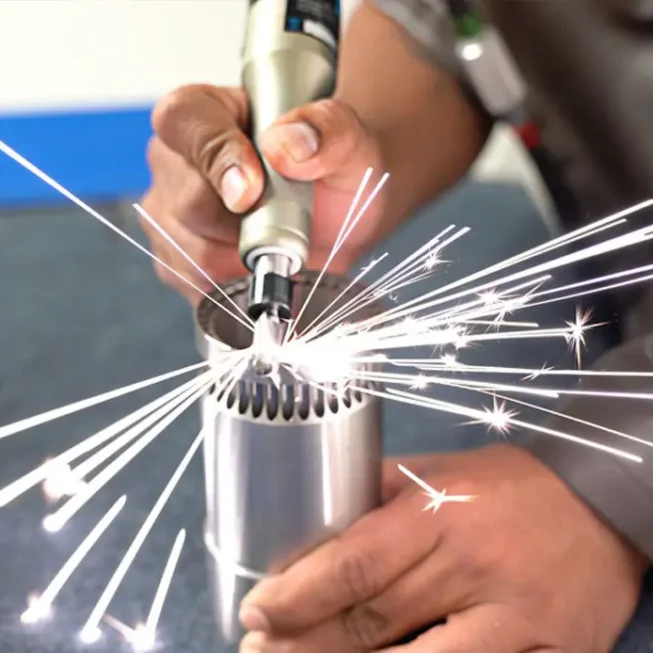

High Speed & Power

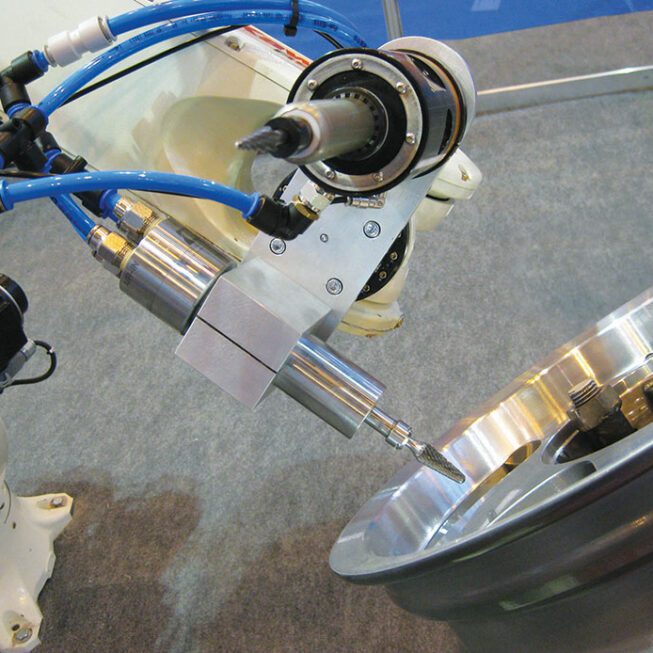

Speeds of 25,000 – 90,000 RPM are available with power ratings up to 1.4 HP (1.03 kW). Constant high-speed extends your cutting tool life by making coatings more effective.

High speed makes Air Turbine Tools® ideal for precision micromachining, milling, slotting, drilling and profiling with small tools. You will dramatically increase cutting feed rates and reduce your cycle times.

See the Difference Yourself

Technical Differences

by Category

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].